In celebration of the enduring innovation of Skunk Works®, Lockheed Martin launched Inside Skunk Works, a podcast giving audiences around the world a glimpse into the disruptive innovations, dedicated people and daring Skunk Works culture founded many years ago. Available via Spotify, Apple Podcasts, Stitcher and SoundCloud.

Behind the Episodes: Season 2

Episode 1: Visioneers

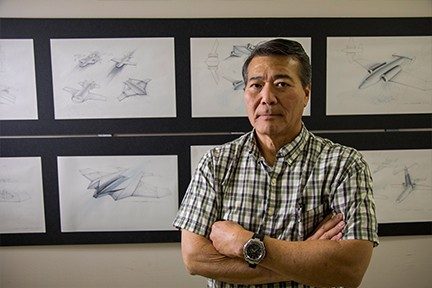

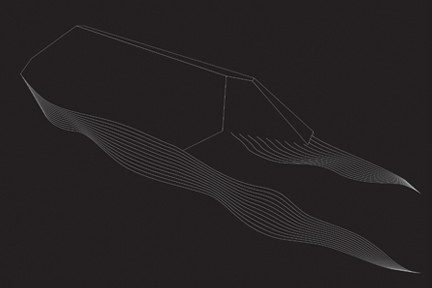

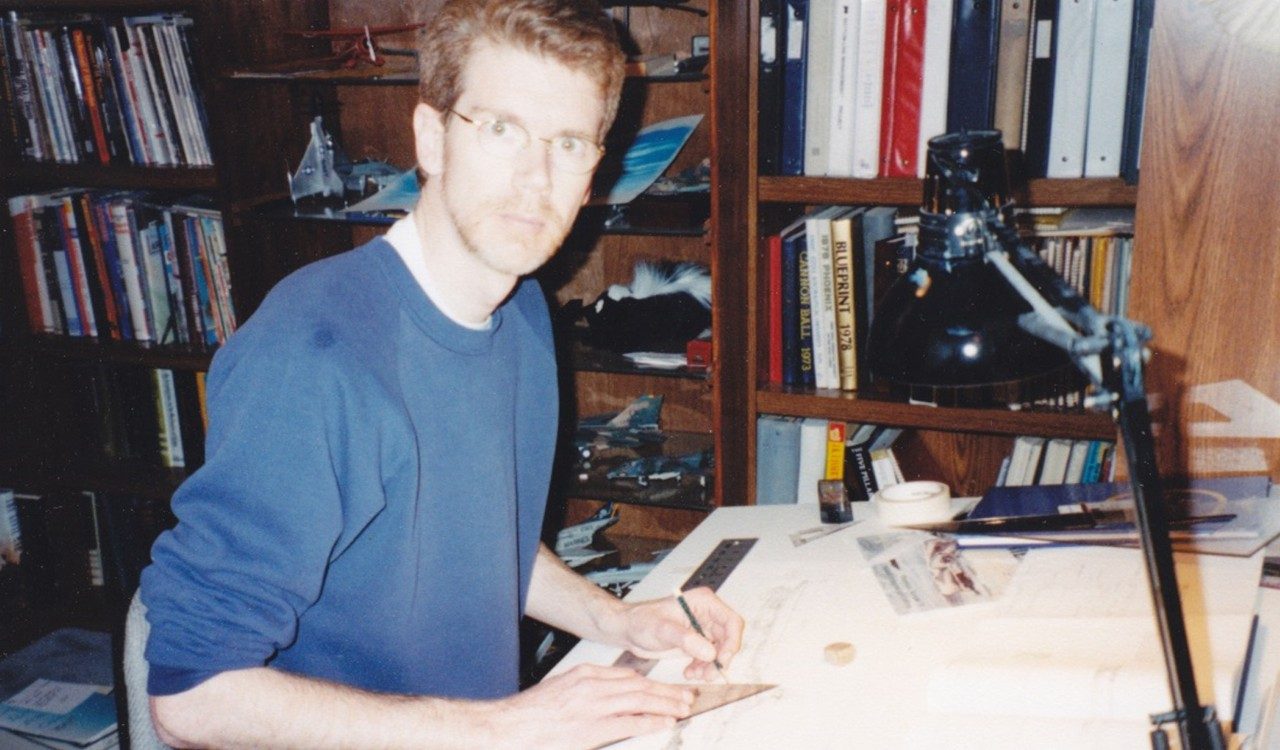

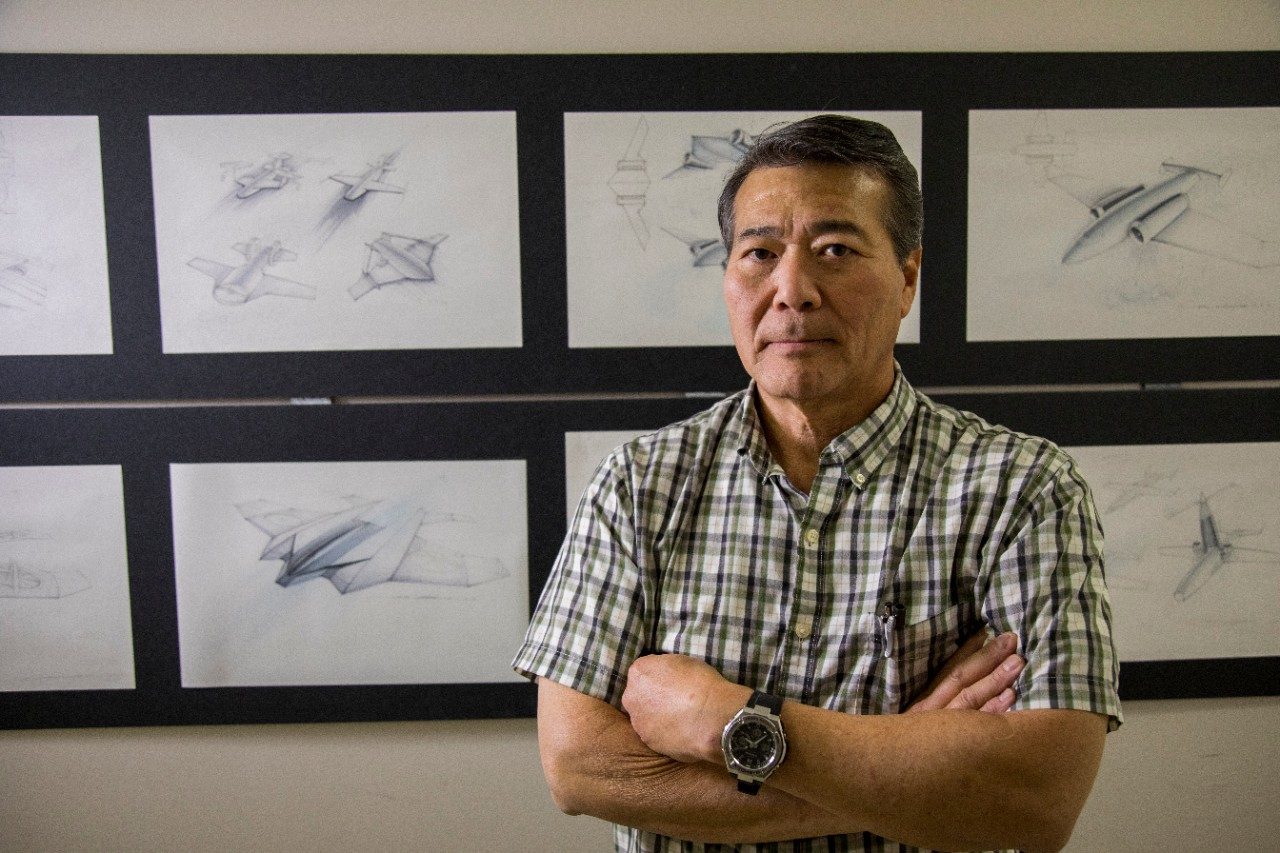

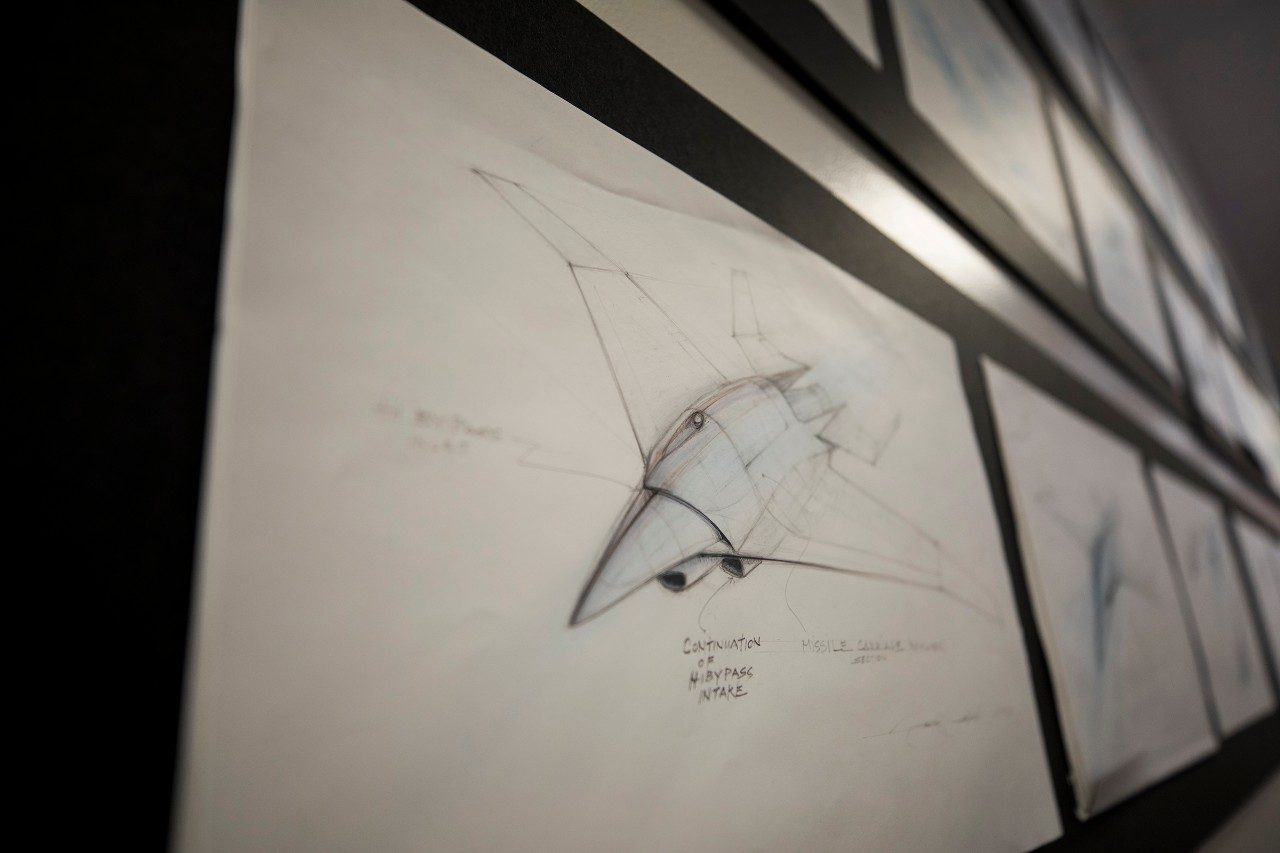

Long before a new aircraft can achieve its first flight, well before the first rivet or bolt is put into place and before even the first piece of hardware can be fabricated, a new design must be created and agreed upon by engineers from a variety of fields. Each aircraft design is uniquely created to meet a specific set of parameters and requirements so that it can successfully accomplish its missions. It is the job of conceptual artists like Eric Watanabe to work with engineers from multiple fields to create never before seen designs for new and emerging aircraft technology.

“My job,” Watanabe says, “is to democratize creativity and sketching.”

While in school Watanabe initially studied drawing, painting and graphic design but was strongly influenced by his uncle, an industrial designer for Panasonic, to pursue his own degree in industrial design. Even as a child, Watanabe was fascinated with exploring the way that things around him worked and fit together, especially machinery. Watanabe recalls his childhood toys often being the focus of his curiosity, frequently disassembled in his search to find the spark within them that made the toys seem to come to life.

“I used to love earth-moving machines - backhoes, bulldozers, cranes,” Watanabe says. “They were like dinosaurs, they all had character, they all had a voice. They’re alive. They’re monsters.”

In design, as well as life, it is important to take in and draw inspiration from your surroundings and to maintain a childlike sense of wonderment and creativity, according to Watanabe.

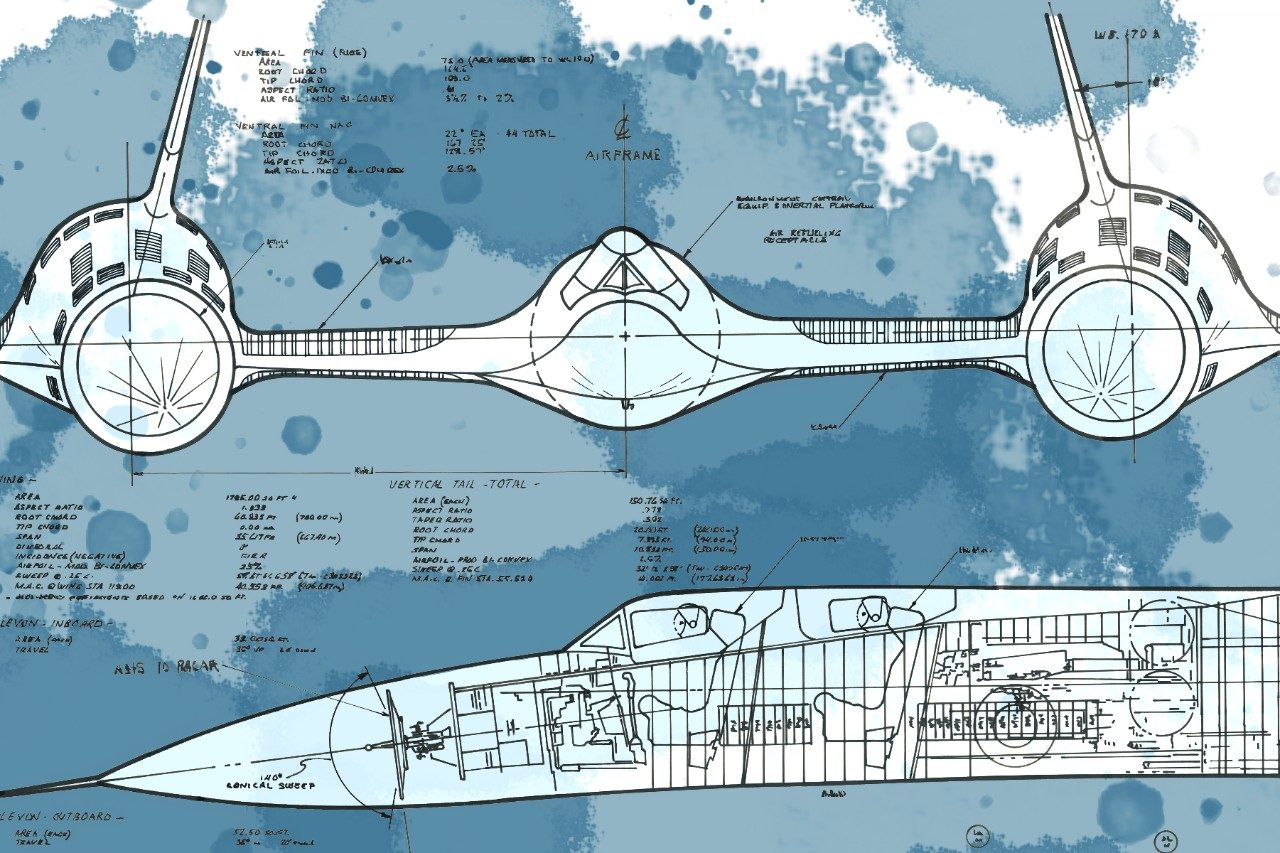

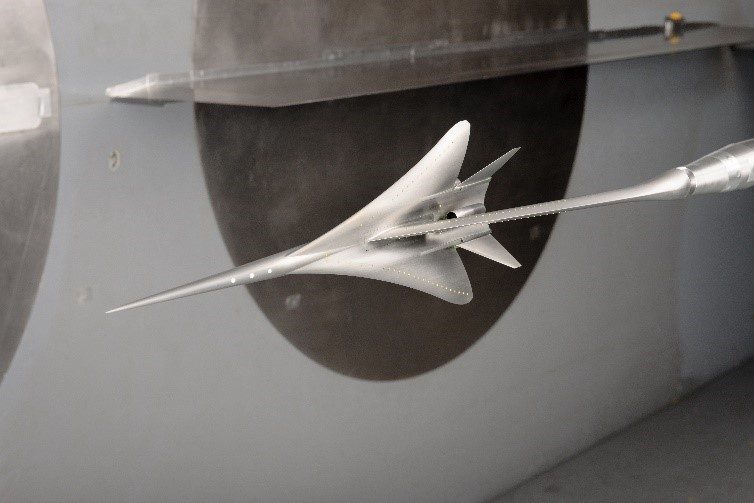

A new concept usually begins only as a description of its mission and the parameters that it must meet. From there the engineers will give a briefing that can include a very rough preliminary concept sketch. Then designers, like Watanabe, create a wire-frame sketch of the product that allows for the concept to be seen all the way through; a skeletal plan of the aircraft to come. At this point the collaboration across fields goes into overdrive to modify the design and build up the full design around the wire-frame concept.

Episode 2: Wolf Pack

1st Gen

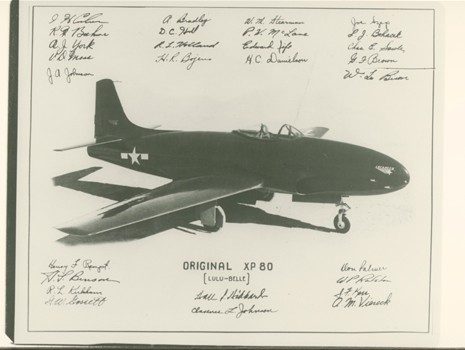

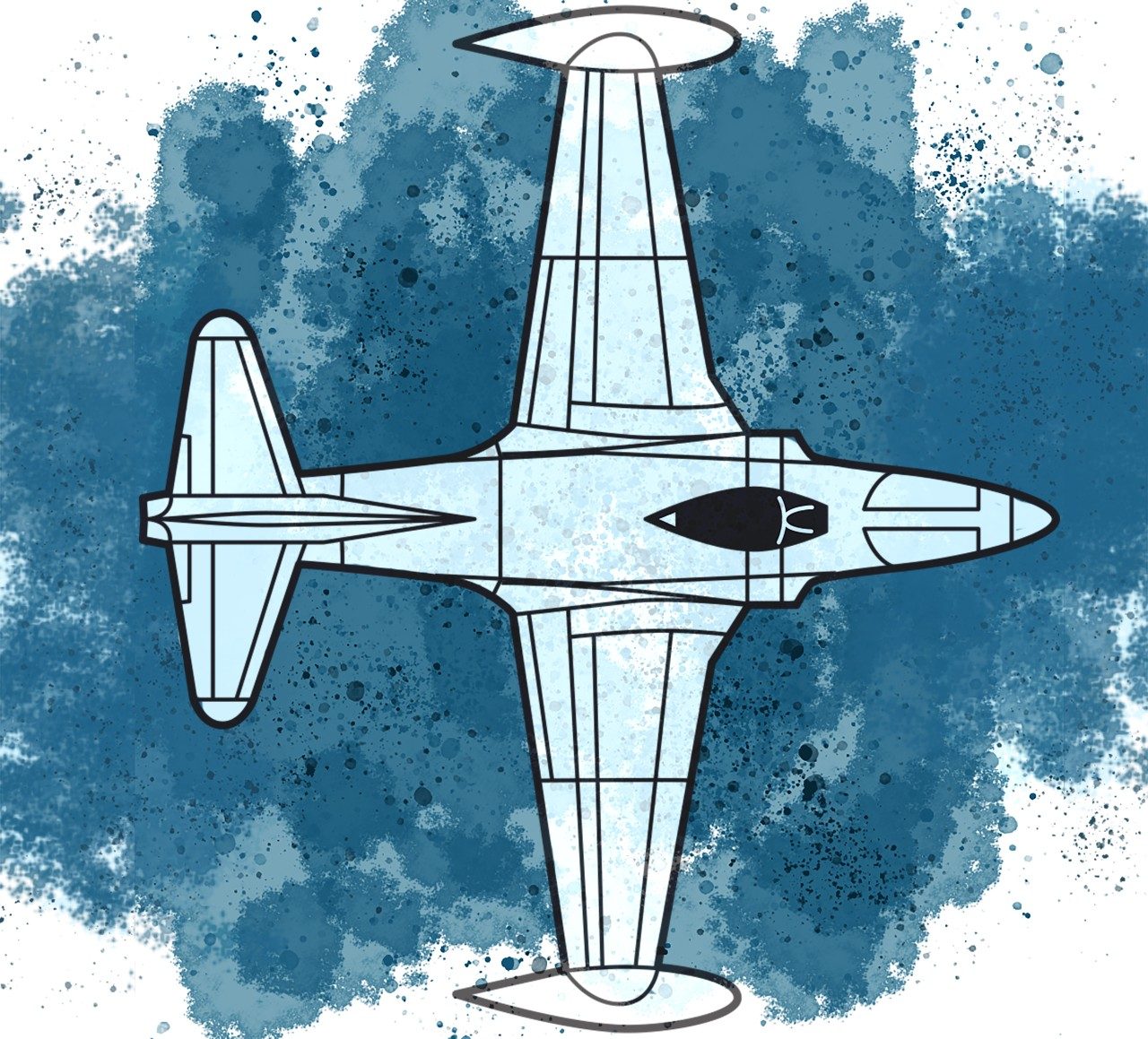

The first fighter aircraft to feature jet propulsion emerged in the 1940s, near the end of WWII. These aircraft traveled at subsonic speeds when flying level and were not drastically different from their propeller driven counterparts at the time. Combat engagements had to be conducted within visual range, and there was no form of radar or defensive technology within the aircraft.

2nd Gen

The advancements in technology and the ongoing tension of the Cold War saw further advancement in jet fighter systems between the mid-1950s and 1960s. In addition to incorporating new technology and afterburner, the swept wing jet fighters were now able to break the sound barrier and travel at supersonic speeds. Combat engagements still occured primarily within visual proximity, though emerging weapons systems began to pave the way for engagements beyond visual range. The anticipation of nuclear warfare and beyond-visual-range combat lead to a focus on Interceptor and Fighter-Bomber aircraft, as opposed to aircraft designed for close-range dogfighting.

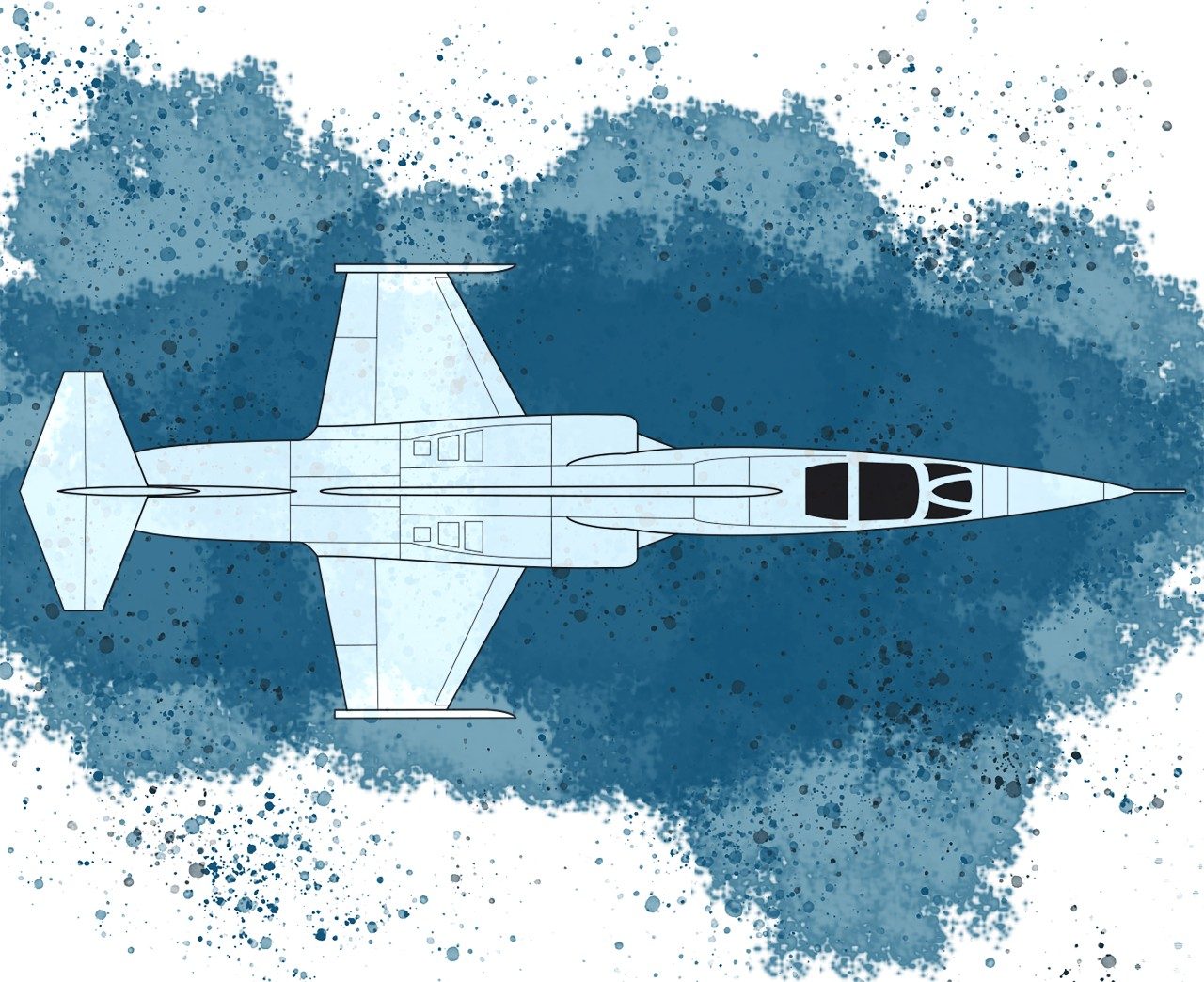

3rd Gen

There was a change in priority between the 1960s and 1970s, during the Vietnam War, and close-range maneuverability and attack capabilities became a primary focus of third generation fighter aircraft. Aircraft incorporated more advanced avionics and aerodynamic design enhancements, allowing for sleeker and more maneuverable designs. Third generation aircraft began to identify the need for “multi-role” fighters that would be capable of accommodating versatile mission parameters as needed. Evolving missile and armament technology combined with advanced radar systems allowed for more accurate engagement from beyond-visual-range.

4th Gen

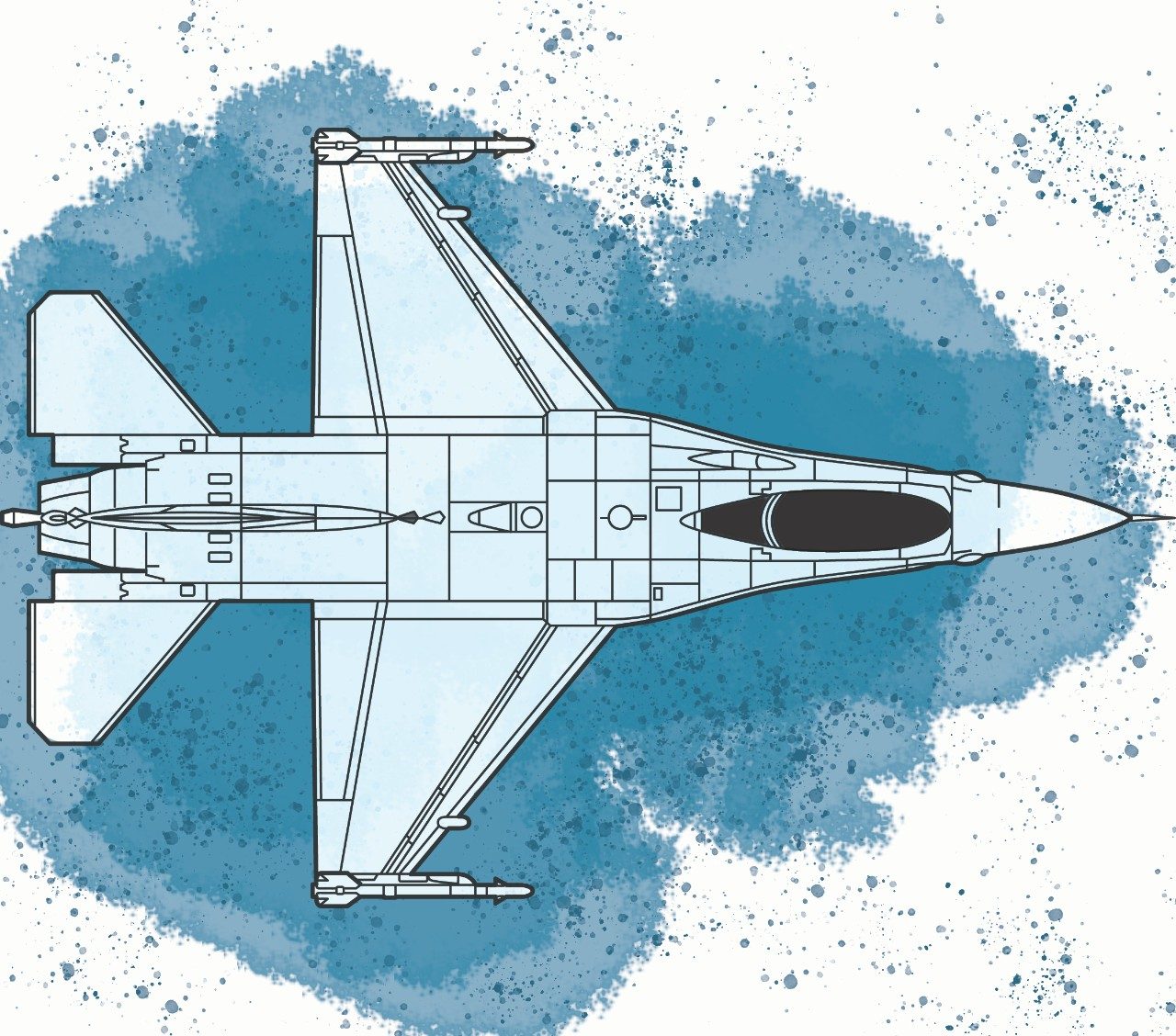

Covering a broader span of time, developed between the 1970s and the 2000s, fourth generation aircraft still remain in service today. Their multi-role capabilities, or the ability to take on air-to-air as well as air-to-ground roles as needed, make them a valuable asset in combat. The F-16 became the first aircraft to incorporate a Fly-By-Wire system. FBW utilizes computers to allow for electronic control the aircraft, as opposed to the previously used hydraulic systems. In addition, use of heads-up display and hands-on-stick-and-throttle systems help pilots maintain focus without needing to remove their hands from flight controls or frequently look down into the cockpit. Advanced avionics, radar, and stealth developments also mark the improvements seen in fourth generation aircraft.

5th Gen

The current fighter generation, fifth generation aircraft, are in a state of ongoing development and production. The F-22 Raptor developed initially by Lockheed Martin’s Skunk Works program opened the door for fifth generation classification, and from there the development of the F-35 Lightning. The advanced avionics systems and engineering, high stealth capabilities and miniscule radar profile, in addition to advanced onboard computer and processing systems form a stealthy multi-role fighter aircraft unlike any seen before. An array of sensors and computer systems provide pilots the ability to “see” through the aircraft, identify threats prior to being detected themselves, and to communicate information to other aircraft via a network system, creating an advanced level of situational awareness and airspace superiority.

At the time of the F-22’s initial creation, there was no classification for fifth generation aircraft, but the newly created fighter jet certainly exceeded the qualifications of the generation preceding it. In true Skunk Works fashion, engineers and aviation experts worked together to officially create the fifth-generation classification, setting precedent for future expansions of generations as technology progresses.

Episode 3: Trusted with Secrets

He has traveled through four continents and 24 countries, narrowly escaped rocket and improvised explosives attacks, received a Joint Service Commendation Medal, has been in a plane crash while transporting classified materials and has held a security clearance for the entirety of his adult life. It sounds like a story straight out of Hollywood, but for Ward Albin these situations are all far from fiction.

Albin joined the military early and served in the Air Force with the military police. After leaving active duty and transitioning to the Air Force Reserves he had decided to pursue a career as a police officer. In the meantime, a friend convinced him to apply for a position with Lockheed Martin, as a temporary job, while looking for something in law enforcement.

“Just on a whim I went down to Lockheed Martin and an employee directed me to where the office was that you can fill out an application and I just walked up and asked for an application, filled it out, and had a job offer later that same day,” Albin said.

With a background in security and the fact that he already possessed an active security clearance Albin’s skill were in high demand among an industry experiencing rapid growth and the emergence of multiple sensitive projects. The call with a job offer came in before he had even returned home from applying for it and he joined the security team for Lockheed Martin Skunk Works® in 1984.

Thirty-five years later, advancing technology and ease of access to information has heavily impacted the way that security professionals, like Albin, conduct their operations. From the rapid availability of resources for stories to be checked against to the ever-increasing threats of information leakage through emerging platforms, the technology available in today’s modern world has created an entirely new security landscape than what Albin first encountered in the 1980’s.

“It’s harder. Our job is a lot harder because there’s so much information out there and everything can be checked,” he said of the new challenges facing security operations.

After his initial six months working as a security guard, working night shifts and still pursuing law enforcement options, Albin was offered a new position as a Security Representative for the Special Projects. He agreed to give it a try and soon all of his plans to change careers went out the window – he was hooked.

In addition to overseeing security operations for advanced development projects Albin spent a year working in the communications vault. The Vault, aptly named, was a room buried deep below one of the Skunk Work’s buildings secured by a thick metal safe-like door containing multiple machines and phones for relaying secure information. While there Albin assisted in securing the transmission, receipt and transportation of highly sensitive and classified information.

“We had message traffic coming in from all over the world, because we had offices and activities going on around the world,” Albin said. “My duties were to bring message traffic up to Ben Rich (the former Director of Skunk Works), selected stuff, for him to read every day.”

Transporting classified materials comes with its own set of very specific and very strict rules that must be adhered to as a matter of safety and national security, whether transporting it across the hall or across the country. No stranger to Murphy’s Law, Albin has experienced situations turning from bad to worse while transporting classified materials. One of his most memorable moments of bad luck occurred when he was involved in a plane crash while transporting classified materials at an airport that had been the scene of a drug and firearms bust only a week before.

“We ended up in the drainage ditch, and we were shaken up and a little bruised but were largely unhurt,” he said. “Our Plane had a bent prop and a damaged wing. It was interesting, as we climbed out of the airplane and out of the ditch, we were shortly met later with the volunteer fire department at the airport and the local sheriff. As we’re climbing out trying to figure out ‘well, what do we do next?’ the sheriff started to ask a lot of questions and he was very suspicious of what we were doing – of course we had these brown opaque wrapped packages along with some crates.”

With their cover story falling apart before their eyes and the prospect of arrest looming closer, they made the decision to inform the sheriff of their identities and that they were transporting ‘sensitive’ material, as well as to show him their credentials. Avoiding injury, arrest, and compromising the materials, Albin and his partner were able to rent vehicles to transport the materials across the country in time.

Albin admits that the cover story used for that particular assignment was not one of the strongest, especially taking into account the surrounding circumstances. Most cover stories are created in a way that sheds enough truth to lend the story credence but omits aspects that can expose anything sensitive, he explains.

“The best cover stories are a high degree of truth,” Albin said. “There’s just enough off that you don’t have to lie – you’re just telling them 80 percent of it, and then the 20 percent remainder you just don’t talk about.”

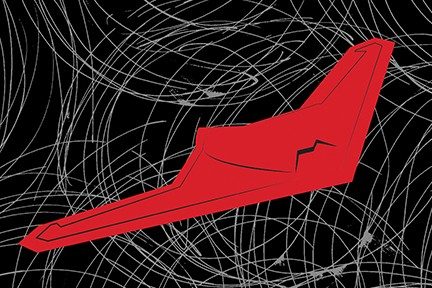

Episode 4: Dull, Dirty, Dangerous

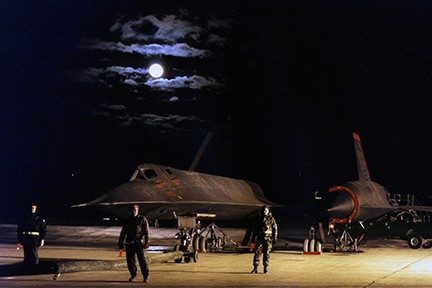

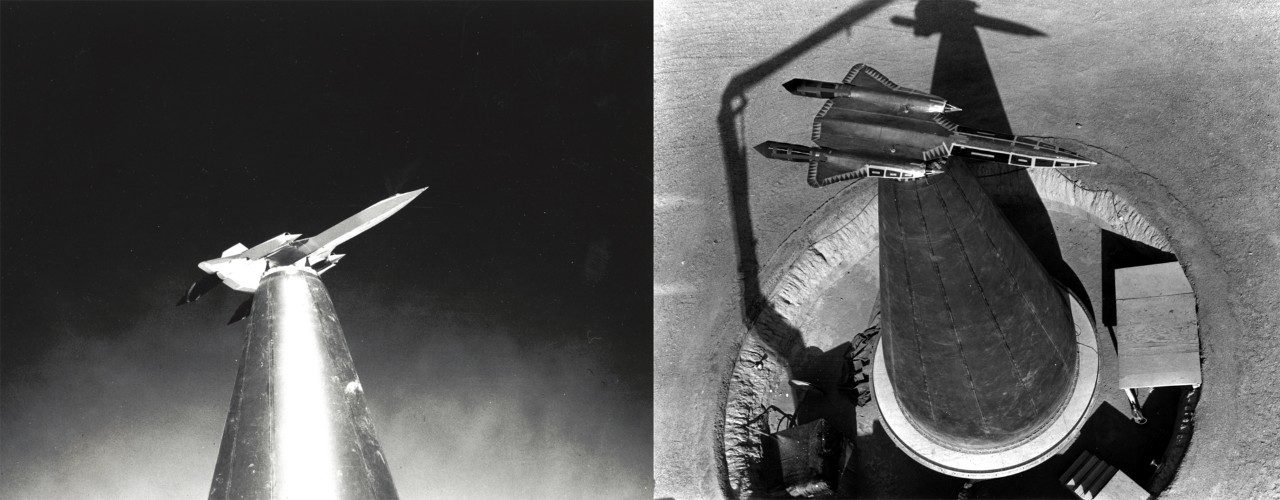

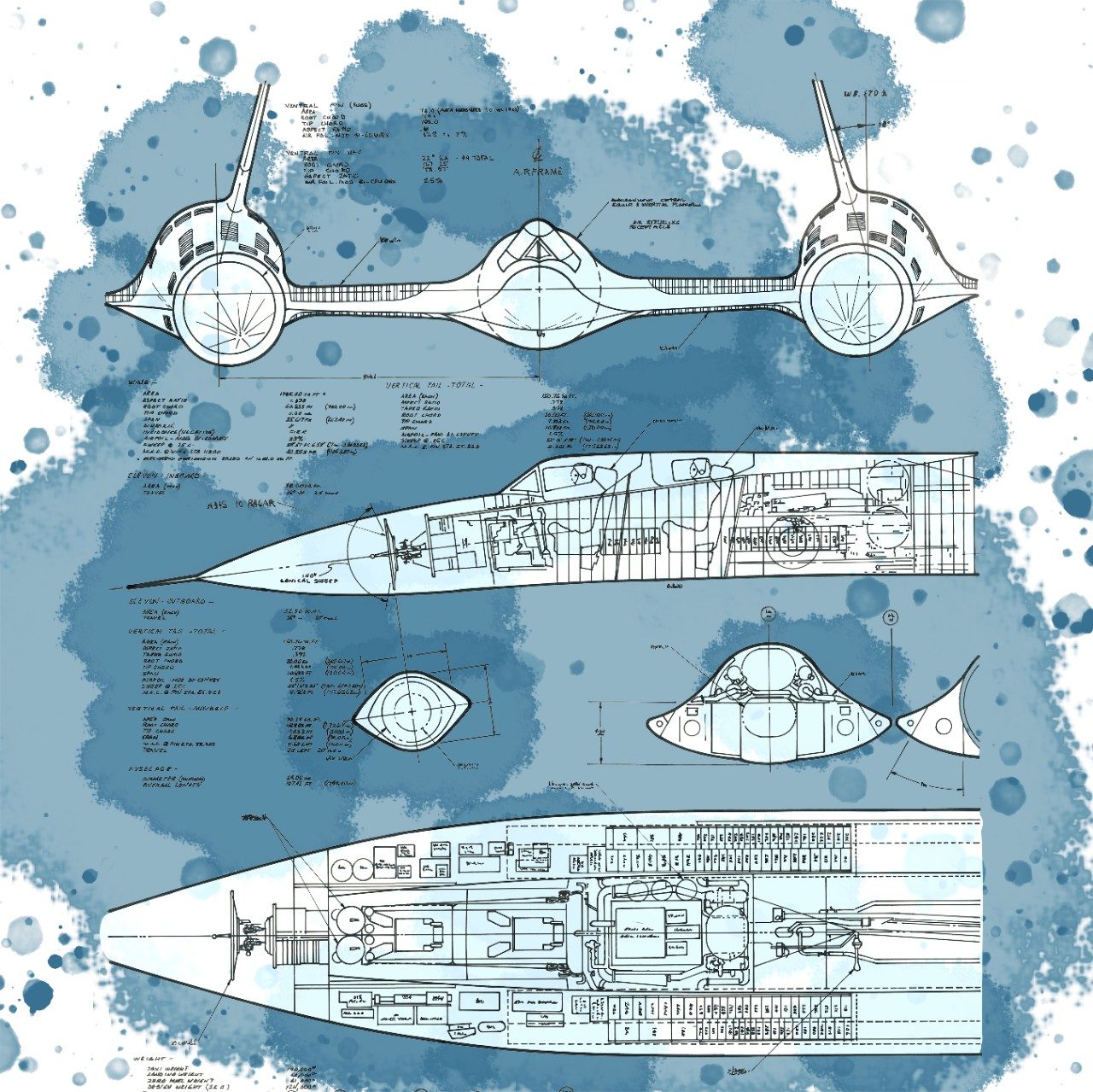

Project “Tagboard” began officially in 1963, launching a mother-daughter reconnaissance duo unlike any seen before them. In an effort to find new ways to keep pilots safe in hostile air space following an incident in 1960 when pilot Gary Powers was shot down on a reconnaissance mission, Lockheed Martin’s Skunk Works division leader Kelly Johnson created a concept for a new unmanned aircraft system. Originally called Q-12, this new system concept aimed to fly high and fast, collecting information deep within hostile territory, and it was designed to be launched from its perch atop the back of modified A-12 aircraft.

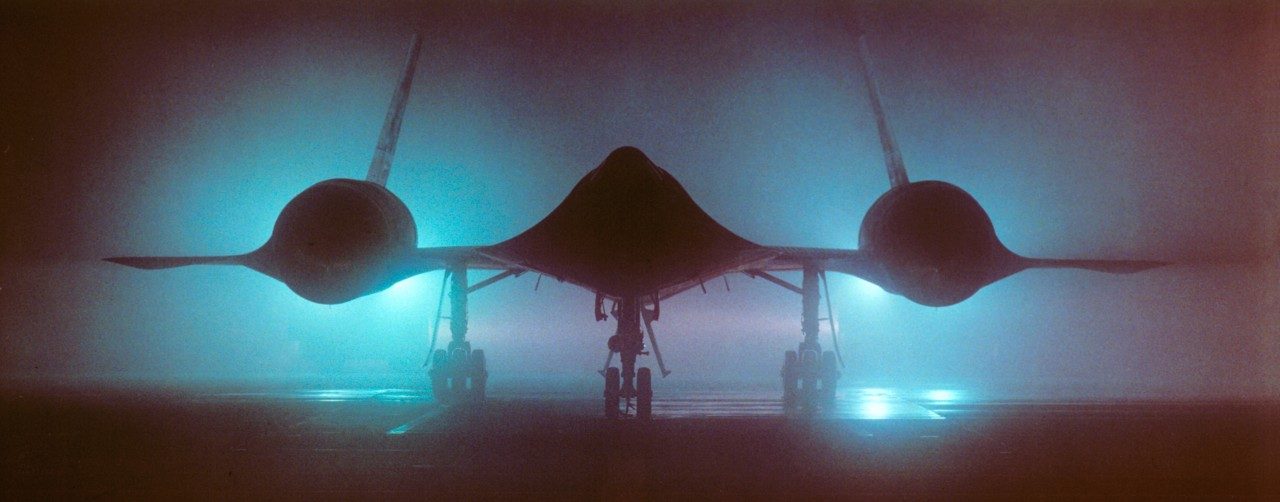

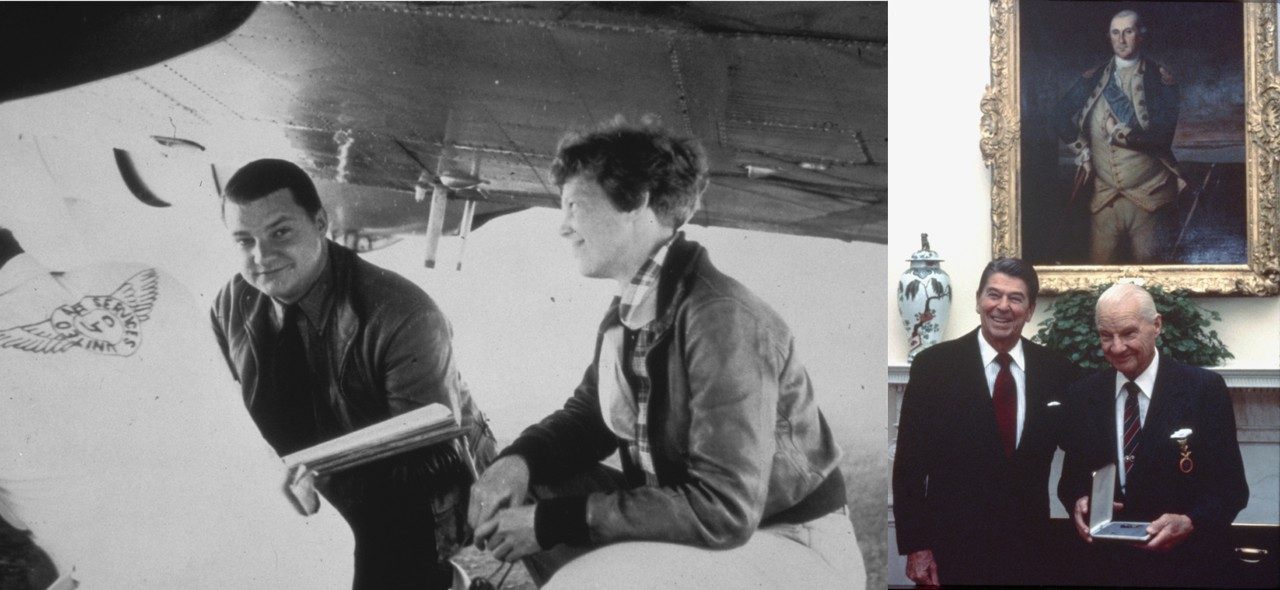

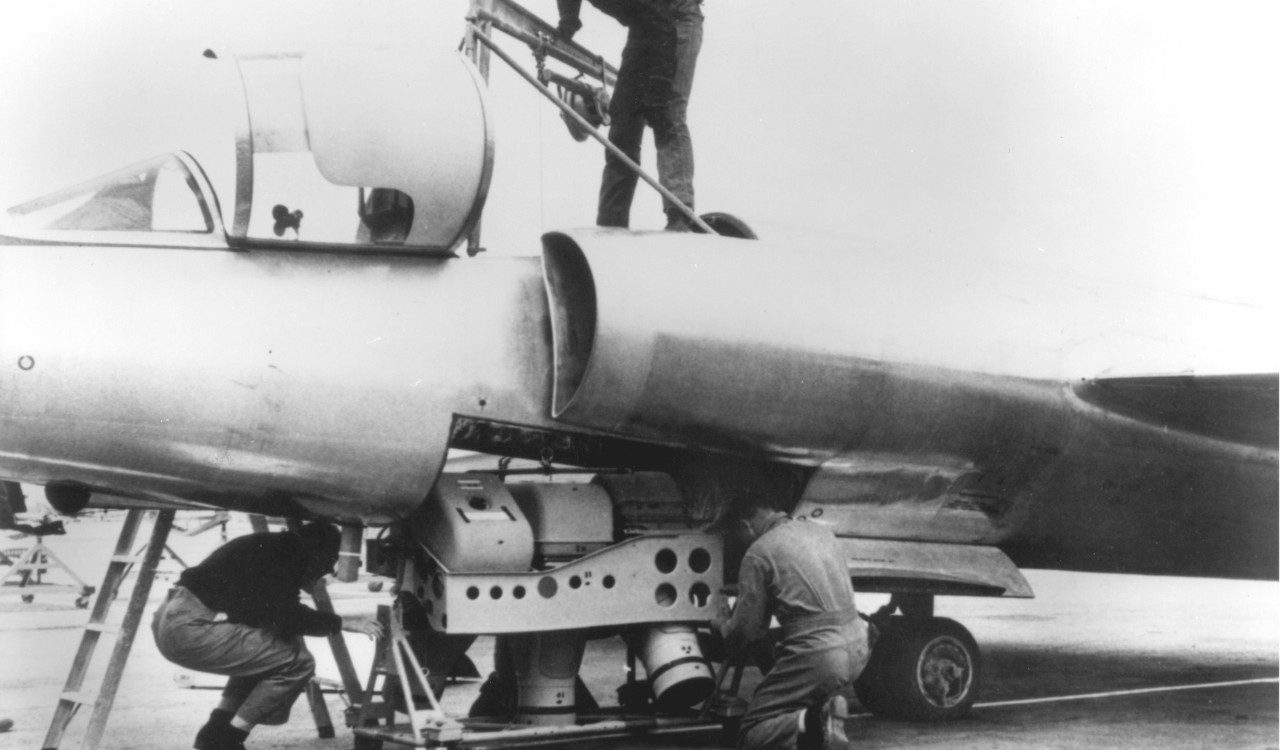

Built for the Central Intelligence Agency, the A-12 was a high-altitude, high-speed reconnaissance aircraft that eventually evolved into the iconic SR-71 Blackbird. A modified two-seater A-12 was created to launch the new drone during flight from a set of pylons mounted on the top of the aircraft. The manned aircraft and drone were redesignated M-21 and D-21 respectively because of their nicknames – “Mother” and “Daughter”.

The D-21 could fly faster than a bullet, reaching speeds exceeding Mach 3.3, at an altitude between 87,000 and 95,000 feet, and for a distance of up to 3,000 nautical miles. Rather than being remotely piloted, the drone was preprogrammed with a flight path and it operated independently following launch, making it a true unmanned aircraft. After flying over hostile territory and capturing reconnaissance images, the drone would return to accessible air space and drop its film canisters to be recovered in air by a JC-130 Hercules, using a technique developed by the USAF to capture film cannisters dropped from early satellites, or by ships in the water. Due to the nature of the areas that it would be flying into, after releasing its cargo of film footage, the drone would self-destruct.

Following a test flight mishap in 1966 the M-21 aircraft was retired, and alterations were made to allow the modified D-21B drone to launch from under the wing of a B-52 bomber instead. The D-21B had to be outfitted with a large rocket that could propel it up to necessary speeds after being deployed from the under-wing pylons of the slower aircraft. This new system of launching the D-21B underwent years of turbulent testing and the drone eventually conducted four operational missions before being retired in 1971. Despite its short-lived operational career, the D-21 remains an integral part of unmanned aircraft history and helped to pave the way for work being done today on intelligence, surveillance and reconnaissance unmanned systems.

Episode 5: Dutch 51

Transcript of Interview with Bob Gilliland, Steve Justice and Robert Gilliland - Recorded on February 23, 2019

Steve Justice: We want to walk people through some of the conversations you and I have had.

Bob Gilliland: Well, I remember one right now.

SJ: What?

BG: A lot of people out there call you the new Kelly Johnson. We have to get that in there. I bet you haven’t forgotten that.

SJ: No, I haven’t and I’m very flattered by that, that you would even think that since you actually knew Kelly, and hopefully they just edit that out and don’t use it.

BG: I hope they do use it!

SJ: (laughs)

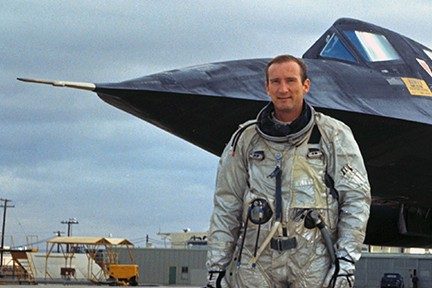

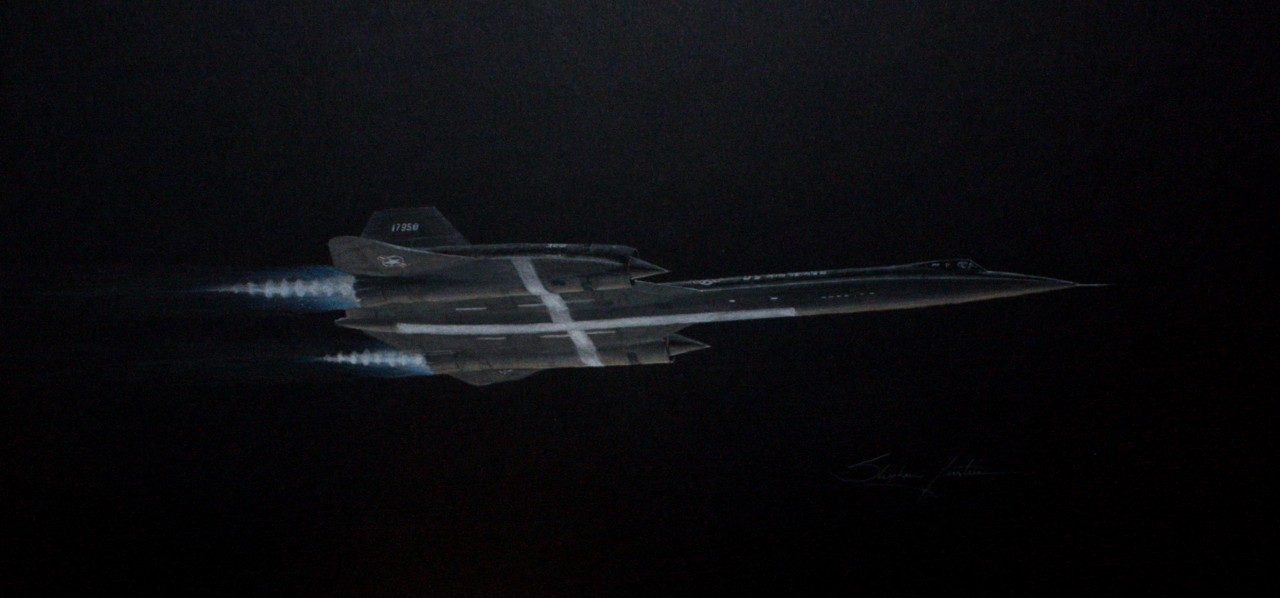

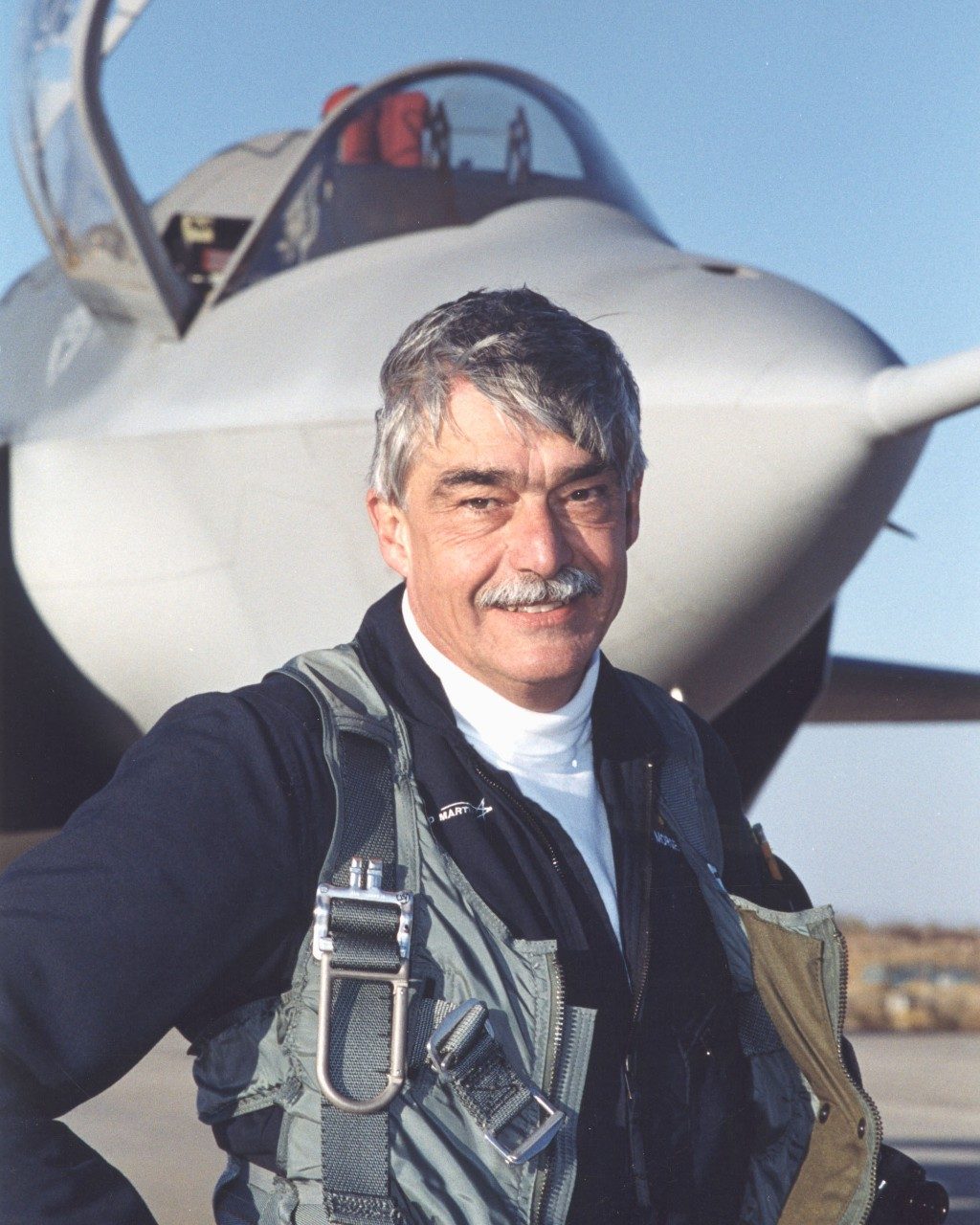

Narration: You may recognize Steve Justice, retired Skunk Works Director of Advanced Development Programs. Earlier this year in February, Steve met up with his friend, Bob Gilliland. Every time they got together Bob would tell stories about his time as a pilot in such a cool, casual way as though everyone must understand what it’s like to fly in an SR-71 for the first time.

SJ: You know, when I told my wife about it, it’s like we’ll always leap at the chance to go out and visit with Bob and his son Robert. And of course Bob comes fully prepared. He has his flight suit with him and a bunch of memorabilia, a number of books that had the airplanes that he flew in it. It was so good to see him again and you know I’m sitting across from this guy that had more flight test time of Mach 2 or Mach 3 than anybody else. That’s the only pilot to have flown every version of the Blackbird, to have worked with all of these icons in the industry and was just as down to earth as you could possibly get. What an honor it was to be able to spend time with someone that lived what I only get to read about. I’ll carry that always.

Narration: On July 4th, 2019, Bob passed away at the age of 93. We are honored to share the stories we captured that day back in February.

SJ: People need to understand where you came from.

BG: Well I was from Memphis, Tennessee and my main interest there was not getting the Mississippi river and me in trouble. Then I went away when I was 14 to Webb’s School near Nashville and my dad had even gone there. He wanted us to get a good education and he knew that’s where I could get it.

SJ: So what year did you graduate?

BG: 1944, when World War II was still on, and I wound up at the Naval Academy.

SJ: What did you do when you got out of the Naval Academy?

BG: Well let me tell ya. I graduated but not into the Navy. I elected to go into the U.S. Air Force because they said that they would put us right into flying, and so I got sent to San Antonio, Texas. That’s where I first soloed.

SJ: So did you always want to fly?

BG: I think I thought I’d like it.

SJ: So you go into the Air Force, and do you immediately go into pilot training?

BG: Yes. After I finished up in San Antonio, then I went over to Arizona, but they had a rule over there that if you were over six feet tall or over 180 [pounds] you had to go to big bombers. And I was over on both counts. Another guy from the Naval Academy, but he was a short guy, he was ordered to go over there to San Antonio but he’d get to fly fighters there. So Saturday night I knocked on the door of the commanding officer and he was having a bunch of people there. He probably didn’t know because we shook hands and said, “Come on in.” And I said, “Well Sir, I’m here on an important thing if you’d give me two minutes of your time.” He said, “What’s all this about?” and he knew I was from the Naval Academy and I told him that I knew this other guy from the Naval Academy and I told him that he wants to go into bombers and we would like to reverse it if you can. He said, “Come and see me at 8 o’clock Monday.” So I did. And I got 50 copies of this new change of assignments and that did the job.

Narration: Bob was an experienced pilot and flew virtually every aircraft in the Air Force’s inventory. He encountered many close calls and challenges during flight and was known for successfully navigating them.

BG: One time I got up, I pulled up and went way high like that and then stalled out and I had to get it out of a spin.

SJ: Oh, it went into a spin in a T-33?

BG: Yeah.

SJ: Yeah. Ok. (laughs)

BG: I wasn’t planning on all of that!

SJ: So you’re in the Air Force. Did you move to operational airplanes at that point?

BG: And I put in for I and Jimmy Hartinger. We were big buddies in flight school. And he had put in for Fürstenfeldbruck which was north west of Munich, Germany. The other base was on the south side of Munich, Germany, so I got assigned to one and he got assigned to the other.

SJ: So what did you fly in Germany?

BG: I flew the P-47, a tailwheel with a four bladed prop.

SJ: What year was this?

BG: We got there in June of 1950.

SJ: So about 5 years after the war at that point.

BG: Yeah.

SJ: So you’re flying P-47s and do you finally get jets?

BG: Oh right away! In fact I made a comment. I said, “What’s this hunk of junk?” talking about that because I had already flown jets. By the way, I went to the Pentagon and I went into this guy’s office and the lady tried to prevent me from going to the Pentagon where I had never been before and so I talked to him and I said, “I’d like to see if you could get me to be based in the Gulf of Mexico south of the Pentagon.” And so I got assigned there and it was close to Memphis and I did get a chance to go back and forth from Memphis a little bit.

SJ: To visit family?

BG: Yeah.

SJ: After you finish flying down on the Gulf you moved up to Knoxville?

BG: My dad he called me up when I was down there in the Gulf of Mexico and says, “I’d like you to come up here and you can join the Air National Guard and help me and my work.” And so I took him up on this and called the Guard and they said, “Hell yeah! We’d like have you in the Memphis Guard.” So I was in the Guard in Memphis and then got in the Guard in Knoxville. And when I got the Guard in Knoxville I flew this airplane here.

Narration: Steve mentioned how Bob came to this interview equipped with his books and memorabilia. Bob was pointing to a photo of the F-104 Starfighter.

SJ: So this is where you flew the F-104 for the first time.

BG: Yeah, and that’s the one that let me get hired by Lockheed.

SJ: Was the 104 an exciting airplane to fly?

BG: Very much so! It was terrific! It was faster than any of the other airplanes.

SJ: How fast did you go in an F-104?

BG: Oh this thing will go Mach 2.

SJ: Did you ever go Mach 2?

BG: Constantly! It was always because of that thing that I got in with Kelly Johnson. He designed it.

SJ: So tell people what it’s like to fly an F-104.

BG: Well one thing about it you’ve got a nose wheel and tires and you got an afterburner, and so if you put on the afterburner and you don’t let the thing roll ahead it could blow a tire.

SJ: So you had to be very careful about using breaks.

BG: Yeah. Exactly. You go burner and you better have everything free to accelerate.

Narration: Lou Schalk was the chief test pilot of Skunk Works® at the time and he recruited Bob to join Lockheed.

BG: And we were in Downtown Burbank and he says, “How would you like to come over here with me?” And so I said, “Ok. Tell me about it.” He says, “I can’t.” I said, “How do I know I would like coming over there with you?” He says, “You don’t.” So that was the conversation we had. It was a beautiful day while we were driving.

SJ: Why did you decide to take him up if you didn’t know about it?

BG: I guess I knew they were doing something secret and good so that’s why I assumed that would be the case. So Kelly Johnson called me over to his office. He knew I was flying this…

Narration: Once again, that tap is Bob pointing to a picture of the F-104.

BG: So he said, “I’ve got something that flies higher than this, flies further than this,” and so then he stands up and it was just me and him in his office and he said, “Now let’s go and take a look at it.” And so that was his secret one that we hadn’t flown yet.

SJ: This was the A-12 Oxcart, the CIA [aircraft]?

BG: Yes. Only fighter pilots could fly that.

SJ: Ok. So Kelly walks you over to this hanger and you walk in…

BG: Yeah. And I could tell it was high and fast and heavy.

SJ: What did you see when you walked through the door?

BG: Nothing. They didn’t have any black stuff on it. It was 94% titanium. That’s what I could see on the first time I looked at it.

SJ: So was it still being built when you saw it?

BG: Yeah. This thing was under construction. Oh and then after that, since it wasn’t ready, Kelly told me to come on over in two weeks. And I said “Well, Levier wants me to go over to Europe again and fly for the Germans and the Italians.” And so then Kelly says, “Well, we don’t have anything ready to fly yet and it’ll be a while, so you might as well go over there again and do that.” So I did and I went briefly to Germany and then I went to Italy and so I finished up with those guys. I got back on a Sunday and I met with Kelly. We would always meet at 7 o’clock on Mondays and the very next day I got a subsonic flight in a secret area.

SJ: So the very first flight in a Blackbird you did was with one of these CIA A-12s?

BG: Yeah.

Narration: Lou Schalk, who recruited Bob, was the first pilot to fly the A-12 Oxcart, a single seat aircraft operated by the CIA and the precursor to the SR-71. Bob became one of the A-12 test pilots.

SJ: Ok. So you fly the A-12 the first time. Was it still kind of in its natural metal color or had it been painted black yet?

BG: Oh no. They didn’t have anything painted black yet. That happened later. One thing I forgot to mention that we had a different engine at first too.

SJ: Yeah. You actually had the Pratt & Whitney J75s inside that.

BG: Yeah, exactly. And so when you’d get the thing you’d accelerate on out and climb and then that’s when we’d blow engines all the time. In the beginning we would blow very frequently before we moved out of the J75s we would be able to go beyond the 3.2 Mach.

SJ: When you say blow an engine, the engine wouldn’t blow up?

BG: It wouldn’t destroy the engine. They could go back and fix it but it would blow up as far as you were concerned.

Narration: Bob is describing an engine unstart, where the compressor of a supersonic aircraft’s engine suddenly stalls. Steve describes what a pilot would experience during an unstart.

SJ: One engine stops. At that point as I remember, the Blackbird has when it’s at cruise has around 15,000 pounds of drag on it. Basic drag. And when you get an inlet unstart it’s about 7,000 pounds of drag that shows up on one side of the airplane, extra, all of a sudden. So the drag goes up by 50% on one side of the airplane causing the airplane to yaw violently to one side. The airplane would hit the pilot in the helmet on the side that the engine was still good. That’s how he knew which engine was good.

SJ: When the inlet would unstart and you would try to restart it…

BG: Generally they would restart it once you slowed down.

SJ: It would restart? Do you have any idea how many unstarts you experienced?

BG: No, I don’t.

SJ:A bunch?

BG: Yeah. It was part of the program.

SJ: Every flight?

BG: Yeah. There was pretty much an unstart on every flight.

Narration: All experimental aircraft require incremental test flights to slowly expand the operational capability of the aircraft. Every test pilot uses test cards to make sure they hit every test point. Bob flew A-12 speed runs which required he fly up toward Canada and down the Pacific Coastline. The A-12 could reach speeds as high as Mach 3.2. At this speed the turn radius is the size of a western state.

BG: We would take off and go north and so if everything was going good we would let it bag it up to a 30 degree angle and start swinging it up so you wouldn’t enter Canada. That was a no-no. Everything went really good.

Robert Gilliland: Although it would have been tempting for my father to see if he could just go a little faster…

Narration: This is Robert Gilliland, Bob Gilliland’s son. You’ll hear more from Robert throughout this episode.

RG: …he stayed exactly within the flight profile and obviously that would be confirmed by the instrumentation on the plane. And I think that that’s a trait that Kelly liked. That if he set a profile on a flight that he wanted it followed to the “T”, he didn’t want any deviations. It was too much at risk. That is the discipline that would be necessary, you know, to be a successful test pilot as well.

BG: I remember when I was way high and I flamed out that I would try one engine and look and it wouldn’t light. Then I’d bring it back and then I try the other engine. Then I kept going down and then pretty soon it was both engines. I couldn’t get a light out of any of them. In the past you would do like that and light it up and everything was normal again.

SJ: Were you going supersonic?

BG: Oh good god yes! I wouldn't be up that high if I weren’t!

SJ: Who was the chase pilot in the 104 that was following you?

BG: Oh that was Bill Skliar.

RG: And he was on his tail and as he was losing altitude and dad kept trying to get it relit, relit, and he couldn’t get it relit. And he was talking to the tower and he said…

BG: I said this looks bad. And I knew they had 30 knots on the ground too.

RG: Right. So as his nose is coming down and Skliar is going right down with him and Dad, every time he would try to get a relight he’d hit the throttle and it would flame out and finally he got one of the engines lit and just enough to get some power going and Bill Skliar…

BG: He was up under me and he said, “It looks like it’s lit now”. And so then I thought, “If I move my stick I could flame out again.” So I went and did a landing out of that deal where I was afraid to move the throttle. And so I landed downwind which was already a high wind. And then touched down I thought I better pick it up like this and slow down a bit, but I got back ok. That was a very close call because Skliar helped me a lot.

SJ: Is that the closest you’ve had to come to ejecting from an airplane?

BG: I’ll say I can’t remember having one closer.

RG: Dad, when he was doing the 104 flight tests, he had five dead stick landings in an F-104 that was another reason Kelly selected Dad for the SR-71 program as well. Because he brought them back.

BG: I had five dead stick landings in this thing. Where the engines quit and you can’t get a restart so you decide to land it instead of eject. But it’d been much safer ejecting on these things.

SJ: Why did you make the decision to try to land?

BG: Because I was flying the damn thing at first seven days a week and on the weekend I could practice a lot. As I got better at it, I had more confidence in it.

SJ: So you felt better trying to land it?

BG: Yeah and I did it too! Five of them. I don’t know anybody that did that many.

Narration: Kelly quickly heard about Bob’s successful dead stick landings from Tony Levier and wanted him to be a test pilot for the SR-71 program.

SJ: You’re one of the few people around that actually worked closely with Kelly and knew Kelly. What was Kelly like?

BG: For one thing he’s paranoid about security.

SJ: Security was very important to him.

BG: Yeah.

SJ: What was he like as a person? Was he smart?

BG: Oh yeah. When he was 27 years old that’s when he designed that other airplane during World War II that went from Burma to Berlin more than halfway around the world. He was only 27 when he did that one.

SJ: Kelly picked you to be the test pilot for the SR-71, right?

BG: Yes, the first flight on that was December 22, 1964. Naturally I would have hoped it would be me.

SJ: Because your job as a test pilot, you took risks.

BG: Sure. It’s part of the job.

SJ: Were you ever afraid to fly?

BG: No, never.

RG: I’ve asked him before, what’s the difference between a test pilot and a regular pilot? And he said, “Well the difference is that most pilots don’t incur emergencies on a consistent basis. Test pilots have to make life or death decisions constantly. You know, one of the things about the SR-71 program that my father did not know on the first flight that it was a milestone program, that is the Department of Defense was going to pay Lockheed a bonus if they could get the first flight of the Blackbird, the SR-71, before January 1 of that upcoming year. It was about month or so before the first flight and Kelly Johnson came up to my father and asked him, “How do you feel about going wheels up on the first flight?” One thing that my father was very good at was that he would always want to talk to the engineers, the different engineers that were involved in the different aspects of the airplane’s design and development, so that he could get a good understanding of what the airplane could and couldn’t do and understanding all the mechanisms and the workings of the aircraft. But he felt very confident in the ejection system so he told Kelly, “I’m fine either way.” And in this case, the SR-71, if the airplane’s landing gear did not retract as needed, then the pilot would have to eject. There’s no bellying in this airplane. And then you lose your prototype aircraft, you’ve lost millions of dollars, and you’ve set the program back years. So when Dad said, “Sure! I’m fine with it.” Kelly said, “Well hmmm… Let me think about it and let me get back to you.” And about a week or so before the first flight he said, “We’re going to go wheels up.” By going wheels up, Lockheed would get another bonus and if they went supersonic on the first flight they would get another bonus. And so before the first flight, they have a card and Kelly set forth the parameters of what the flight would entail and what would be accomplished on the first flight.

BG: So Kelly came up in his two engine Jet Star and then in this case we had three chase pilots. So I taxied out and parked and got in position and then we all rolled down the runway at the same time and took off and went up to about 25,000 feet.

Narration: Bob flew north up over Mammoth Lakes, California.

BG: So I got over the mountains, because even then it drops a sonic boom. So I went burner. Every time you go burner in this airplane one will hit but the other one won’t so you go like that and when you both got them you’d accelerate. So when I got up to around 1.8 Mach that’s when I got a problem.

Narration: A red light flashed on the instrument panel indicating the canopy was unsafe, so Bob pulled back the throttles and analyzed the problem. He turned to his right and left to determine if the canopy was secured properly. He determined that the air over the canopy was causing it to lift just slightly. A micro-switch triggered as if the canopy was raised during flight. He determined the switch was giving a false reading and that the canopy was indeed safe. He accelerated and ignored the flashing red light.

BG: So I came back and reduced it to minimum burner. And it slowed down from 1.8 down to .04. So I looked to see what the hell was causing that and then I went burner again. At first I thought,” Well this is the first flight and I think they’ve screwed up maybe the way they put the gauges. So I lowered it and I went all the way up to 1.5….

Narration: Robert told us that Bob later commented that if the canopy had in fact blown off, the engineers on the ground would have been very upset asking him, “Why do you think we put that big red light in front of your face?”

BG: ….and there was no problem. When I came back reduced power and Kelly says, “How is your fuel?” And I said, “Fuel’s fine sir.” Kelly said, “Well how about a fly by?” And he had a bunch of people on top of a building and so we just did a nice fly by. Then Kelly says, “How’s your fuel now? Says, “Fuel’s still good sir.” He says, “How about another fly by?” So we did another fly by like this. He had a couple generals there and they wanted one more fly by so we did that but then we had a malfunction and we started leaking fuel and it was leaking out big time so I came around and landed in a hurry. We were real happy that everything had gone good.

RG: When he did the last flyby with the SR-71 in front of Kelly as was requested with the generals, and it started dumping fuel it was a white stream coming out of the tail.

BG: Right.

RG: And one of the generals nudged Kelly and asked, “What’s that?” and Kelly had the embarrassment to say, “Oh it’s just a minor little problem.” But he had later told Dad that, “I wish I hadn’t asked you to make that last flyby.”

BG: (laughs)

RG: “Because it was a little embarrassing with the General nudging me like that.”

BG: Yeah.

Narration: Robert, along with his mother and sister, was actually present for the first flight as well.

RG: My mother got a phone call from one of her friends who was married to one of the employees at Lockheed in the Skunk Works®. To inform her that the flight was going off today. My mom of course knew my dad was a test pilot and worked for Lockheed and she also knew that he was flying something very super secret that he wouldn’t talk about. My dad had told her that he was flying something that he couldn’t discuss but that it would be going off very soon. And so my dad in advance previously told my mom that if she’s able to come out and watch the first flight, this is where I want you to park. So on that morning my mom got the call and she drove over quickly to where the flight was to take place in Palmdale and parked where my dad had indicated. And I was there and my older sister Ann. And so I was just a little guy at the time, I was only 2 years old, my sister was 4 years old. But what happened was when Dad, he rolled out to the end of the runway and then just sat there, there was a 104 behind him just idling and 2 104s were just circling overhead waiting for the rollout down the runway. And when he came overhead at least by the side where we had parked, my mom had recounted to me that my sister and I immediately were just terrified of the loud engines. I think we were both probably in tears at that time and when he came screaming overhead and my mom was there and she said the tears were just rolling off her face. Willing the plane off the ground so to speak. And you know, Dad disappeared off into the horizon.

Narration: Bob received a signed photo from Kelly for successfully completing the first flight.

BG: He put down in the lower right hand corner “To Bob Gilliland. Thanks for a fine first flight.” And then he signed it. I showed that to Tony Levier and he says, “Hell, I made several, a bunch of first flights for Kelly Johnson and he never wrote anything like that for me.” (laughs)

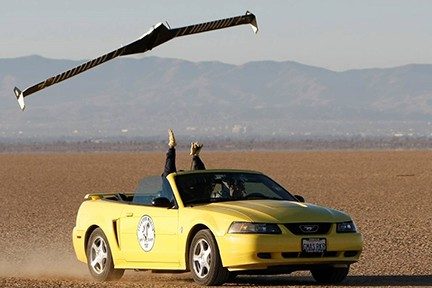

RG: At one point we lived in La Canada Flintridge which is down the hill over from, you have to go over the Angeles Crest Highway, it’s about a 45 minute drive and then you drop into Palmdale where Dad would have to have those 7 a.m. meetings, bright and early. And so he had this Mustang and it was very, it was a new Mustang, very fast and he’d go zipping around over the hill and down into Palmdale to make sure he wasn’t late for Kelly because he said, “Whatever you did, you didn’t want to be late for a Kelly Johnson meeting that’s for sure.” But I remember one day I was sitting in his car and I was in the passenger seat and I punched the glove box open and all these yellow tickets came flying out and I realized at that point when you fly at Mach 3.2 in the world’s highest and fastest airplane it takes a little getting used to go slow again when you’re in your car.

SJ: How did the name Dutch 51 come to be?

BG: That was from the Pentagon. They told you what your code number would be.

SJ: Really?

RG: Each of the pilots all got, you know, all of their call signs were ‘Dutch’ and it was either 51, 52, 53, or whatever. The irony I think is funny is that that Dad’s call sign was Dutch 51 and he flew out of Area 51.

BG: (laughs)

RG: He got a lot of questions asking if that was intentional, but I think it was really random that he just ended up with Dutch 51.

SJ: What did it feel like to be able to talk to people about the Blackbird for the first time out in public. Do you remember doing that?

BG: I would be careful who I, I was used to doing things that were secret. So I just would just keep it a secret as far as I was concerned.

RG: When you’re younger you don’t tend to appreciate the accomplishments of your parents. I knew he flew this black airplane that was really fast and I just thought it was normal. And all the friends that would come over to the house when I was a kid were astronaut and test pilots. So it seemed very normal to me. This is just his job, this is just what he does and there wasn’t anything super amazing about it. Although I do remember one occasion when I was at one of my friend’s homes and we somehow got on the subject of my father, talking about how he flies, and that he flies this black airplane that goes so fast that he can fly faster than a 30-06 bullet. And I remember the parent looking at me like smiling you know with this kind of look like. “Oh isn’t that, what a creative imagination he must have.”

RG: But I just growing up in kind of this shadowy world it was very different, very interesting. And as I got older I got to appreciate it more. Although he did all these amazing things and flew in the world’s highest and fastest airplane, nobody knew about it because it was top secret it was not to be spoken not to be discussed. So he really didn’t attain fame or recognition for what he has done until much later in his life.

RG: It’s very kind of strange in the way that he’s my father and yet I see this American aviation icon. But I look at him as he’s just my dad. He’s just my father that was I think in the right place at the right time, who happened to have all the skills necessary to accomplish the job.

SJ: Is there an airplane that you didn’t get to fly that you would have liked to have flown?

BG: Well I’m sure in mat earlier day I would have taken up a bunch of them if I could of.

SJ: What kind of airplanes did you want to fly? Fighters?

BG: Oh yeah. The fighters! The world’s best.

SJ: The world’s best.

BG: Yeah, but you don’t see anybody, you don’t see those at 85,000 feet. There was nothing comparable that could go 3.2, that’s the maximum speed of the airplane and when you’re going that fast you’re going fast at 85,000 feet going big time.

SJ: What was the view looking out the windows of the Blackbird? I know you didn’t look out much.

BG: Well I was all enthralled with flying the airplane. You know I like doing that. I was doing what I wanted to do. After all, that’s why I left Tennessee and I went all the way over to Lockheed in the first place.

SJ: Let me ask you this. You and I have talked about this before but, you are forever tied to history. When you reflect on being the first person to fly the Blackbird and know that forever your name is going to be tied to that, what goes through your head? Are you humbled by it?

BG: Oh grateful I was in the position to do that. Still am.

SJ: Very proud of that?

BG: I just think I’m lucky to have done it and I would have done it the same way if I had it to do over.

Narration: Inside Skunk Works is produced in Palmdale California and Fort Worth Texas. We want to extend a thank you to Bob’s son, Robert Gilliland, and his family for making this episode possible. For a full transcription of this episode visit LockheedMartin.com/InsideSkunkWorks.

Episode 6: Faster & Faster

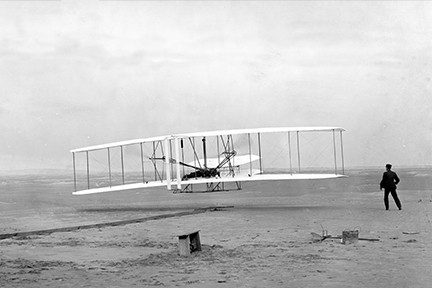

Eric Knutson: It was the late ‘50s, early ‘60s, rather the Air Force and NACA at the time, the predecessor to NASA, that created a series of aircraft that would go very fast, the X series, all flown in the Antelope Valley, ultimately culminating in what’s still is the fastest manned flight, in the X-15 back in the early ‘60s by Pete Knight.

Narration: On October 3rd, 1967, Major William Pete Knight set the world aircraft speed record flying the X-15, a hypersonic, rocket-powered aircraft. He flew at Mach 6.7, or 4,520 miles per hour, and as Eric Knutson mentioned, Pete Knight holds the record to this date. The need to go fast is part of our DNA. From the invention of the wheel to the invention of the hypersonic X-15, humans have been fascinated with moving faster. If you’ve driven a sports car, rode rollercoasters, or plunged your bike down a steep hill, you know the exhilaration of an adrenaline rush.

Atherton Carty: You know, human beings are kind of bound by perspective, right? When you’re walking along the street, then somebody on a bicycle or a car is fast, but when you look up in the sky and see something streaking across the sky, that kind of redefines what fast is. We see a lot of airliners go across the sky, and we see private jets. Typically, the first time that someone sees a combat aircraft in full after-burner across the sky, it’s pretty eye-opening.

Narration: This is Atherton Carty, director of the Technology Roadmaps organization.

AC: Folks that have seen, for instance the SR-71, at Mach 3 and 70,000 feet, streaking across the sky faster than you’ve ever seen any other aircraft fly, it again redefines what the art of the possible is. Aircraft came into being because people realized speed was important. Right? So you think about the way people conducted combat before, it was hand-to-hand, then it was mounted, then it was mechanized. Each one of those generations, they had different things that tipped the balance one way or another. It was bows and arrows, and then it was spears, and then it was single-shot guns, and then it was machine guns, and then it was artillery. All those conflicts were always confined to two-dimensional conflict; it was always fought on the surface of the globe, right? And they were always kind of were inherently limited by how quickly you could move from place to place. It didn’t take very long for folks to recognize aviation as being really important for two things. One, if you could get up above everybody else, it made it hard for them to hit you. You could see them much better, and then if you could also add speed into the mix, you had a clear discriminator.

James Dorrell: Speed is an element, an element of surprise, whether it’s with a weapon or a platform, that is very, very difficult for our adversaries to counter.

Narration: This is James Dorrell. He leads the Tactical Systems portfolio.

JD: Speed, and especially hypersonic speed, is something that is hard to be detected. It gives our allied forces the element of surprise any place in the world in a very short amount of time.

Renee Pasman: You know, the reason you want to be able to surprise the adversary is you want to create chaos in their system.

Narration: By now, you probably recognize Renee Pasman, Director of Integrated Systems here at the Skunk Works.

RP: …which doesn’t tell you what I do, but that’s a feature, not a bug, of my job title. Being able to go faster, you know, they don’t know where you’re going to be, or they don’t know where you’re going, and so they can’t prepare, which means you can do more damage, or take pictures when people aren’t expecting it. So it’s that not being predictable and being faster than they can account for, that creates that element of surprise, which really creates chaos in the adversary, which then gives us opportunities to take advantage of that chaos and complete their mission. But Eric Knutson’s really the person to ask the hypersonics, not me.

EK: So let me take a crack at that. Eric Knutson, Director of Advanced Programs. So what’s the possibilities of hypersonics to all humanity? The Amazon packages will arrive really fast. Although aircraft and flying, really it’s entirety fits within maybe two generations’ lifetime. It’s a very short period, but a lot of it has been dedicated to speed. You go way back when they were simply doing balloons, and they really, you’re at the whims of the wind, and they didn’t go very fast, so it took a long time to go very far, and you really never knew where you were going to go. The need to get to a location quicker became paramount. Speed, and relative to high speed, really didn’t come about until probably the latter part of the ‘50s. That isn’t to say that we didn’t understand things flying fast with various rockets and such; that’s been going on for a long time.

JD: So hypersonic is defined as being more than five times the speed of sound. Mach numbers are how we define speed. Our aircraft today, the F-22 flies greater than Mach 2, the F-35 flies higher than Mach 1. A hypersonic weapon is defined to be able to fly great than Mach 5, and in many cases we’re much greater than Mach 5.

EK: Well, hypersonics is just kind of an artificial limit that we’ve placed, and at this speed you’re going hypersonic, and below that you’re supersonic. Below that, you’re subsonic. So it’s just cases where the speed really makes a difference. Now speed and oftentimes things that go faster or better have a hard cost, so you have to weigh that against what’s the value of having that speed. If I’m shipping things from a factory in Asia, the cost of going fast may not be a benefit. But if I’m trying to get medical supplies or there’s some national emergency, in the United States or elsewhere, the ability to get resources to that location quickly mean the difference between life and death. It’s always been a quest, but with speed comes some challenges. Everything is a tradeoff. So as you get going faster, other things start to happen. In the SR-71, we certainly found that out. Things started to get warm, paint started to want to bleed away. In fact, it was warm enough that the SR pilots would warm their food tubes by sticking them up by the window, which had gotten quite warm by that time. So you have to find a way to deal with the problem of speed. As you go fast, the air gets, like sandpaper it starts to really dig in, warm up, there’s friction.

AC: The air behaves differently at hypersonic speeds. You see much more aerothermal heating at hypersonic speeds. Those things don’t all happen immediately at the same time like a flip of a switch, right? They start to manifest themselves as the aircraft moves faster and faster, so you might see some hypersonic effects at Mach 4, but other hypersonic effects only really start coming in at Mach 5 or Mach 6. And so it’s a speed regime, is the way that we typically describe it, of typically Mach 4 or 5 and above. If we are in an aircraft and we were going to accelerate from a standstill to hypersonic speed, we take off and we start flying, all the way through subsonic speeds Mother Nature gives us a real benefit, which is the disturbance that our aircraft is creating is essentially a sound wave. And so, there’s essentially a warning that can be propagated in front of the aircraft to tell all the air molecules in front of the aircraft, “Hey, get out of the way.” And so, what happens is you find that air flows around an aircraft at subsonic speeds, with some good design and engineering, fairly well. But then once you start getting up to high subsonic speeds, the air in front of the vehicle, our vehicle, has less and less warning, and once you get to the speed of sound, it has no warning because the waves that were traveling upstream to warn the aircraft are the same speed as the aircraft. So there is no propagation, there is no warning. Those corrections, if you will, that Mother Nature applies come in to play and things like shockwaves start getting generated. Shockwaves are these discontinuous waves that emanate from leading surfaces of aircraft, and basically in front of the shockwave the air is supersonic, and on the other side of the shockwave in many cases it’s, well certainly slower, but it’s oftentimes subsonic, depending on the type of shockwave, the angle of the shockwave, and that sort of thing. So the point is, as you speed up more and more, you start seeing these shockwaves all over the aircraft, and what they’re doing is they’re allowing the air to continue to flow relatively smoothly over the aircraft, but it has to slow down when it does it. As you increase more and more in speed, these shockwaves get stronger and stronger and stronger, the skin of the aircraft gets hotter and hotter, and so at some point, the heating itself becomes one of the main concerns. How do I manage that heat? Also, other things that change are the ways that you control the aircraft, how effective the control surfaces are on the aircraft, how effective that the wings are that hold the aircraft, also change. And so, as you move up in speed, from very low speeds to very high speeds, it becomes much more tricky and you probably will use different strategies to control an aircraft at hypersonic speeds than you would, certainly at subsonic speeds and even at supersonic speeds.

EK: So there’s a lot of engineers that have spent a lifetime creating materials that can deal with the heat. On the X-15, the last flight, the one where Pete Knight set the record, where they covered the entire aircraft with an ablative material. At the same time, I believe they were testing a scramjet, kind of the early versions of, can we create something that will give us propulsion? And essentially the ablative material flaked off, burnt up, and by the time they got back down, the aircraft was no longer useable. And the scramjet, most of that melted, too. So there’s a lot of friction, a lot of heat, so you have to deal with that. The other element is, you tend to want to climb up in altitude. So much like we saw with the bridged supersonic jet, they tend to want to go to a higher altitude, and at that higher altitude, now there are safety concerns for the folks on board. You have to be able to pressurize the cabin, if there’s a sudden depressurization, can you get to an altitude where you are not going to cause medical problems with the passengers on board? For the SR-71, those folks flew the airplane fully-clothed in a full-pressure suit. Just in case something happens and they lost pressurization, they weren’t also losing life.

Narration: Another aspect of managing heat and safety measures lies in the unexpected shape of hypersonic aircraft.

AC: So one of the things you’ll notice about hypersonic aircraft that can make you scratch your head, is you think ok, a hypersonic aircraft like the space shuttle, that’s flying at 18,000 miles an hour or something like that, is pretty chunky-looking, right? It’s got big curvatures on the leading edge, it’s kind of blunt, the way that it looks from a curvature standpoint, it’s kind of bulky. It’s a very utilitarian aircraft; it does its job amazingly well, one of the defining achievements, I think, of aerospace. So the space shuttle is far faster than any combat aircraft. But you look at the combat aircraft and they have pointy noses, right? And they have sharp leading edges, and you say, “Ok, well why do they have these sharp leading edges, and why does the space shuttle have this big, bulbous nose and these big, thick edges?” And the answer is that one, some of the places that it operates there isn’t much air at all, so it really only starts to matter towards the very beginning and the very end of it’s mission. But the other things is that the air is behaving with a different set of rules. Right? So it moves around shapes in a different way, it heats in a different way. The reason the space shuttle looks the way that it does, it really wasn’t driven nearly as much by aerodynamics, if you will, as it was by trying to manage heating. And so the point is, Mother Nature gives us different sets of rules to deal with, and that’s why certain aircraft that operate in these different speed regimes look so differently.

RP: So there’s a lot of things that have to be considered. In some ways, it’s not very difficult, right? It’s a very simple equation, if you approach things that way, which is you know, make that much force going forward to counter the force going backwards, and somehow we also have to generate enough lift to stay up. So it’s a very simple equation, but in order to actually make that work, there is a number of things that have to be considered. First and foremost obviously, propulsion, so engines. Jet engines work by making air go through them and combusting things, and so if that air is moving too fast, that doesn’t work. Even the best, most well-designed turbine engine will not work at certain Mach speeds, above roughly Mach 2ish, 3ish. If you want to go faster than that, you need a different propulsion system. And a lot of those types of propulsion systems, like ramjet that the SR-71 used, don’t work well at very low Mach numbers, so then you have to somehow figure out how to make one work with the other.

Narration: Accelerating aircraft to hypersonic speeds is very violent and requires many engineering feats. So what would it be like to take a ride in a hypersonic jet?

EK: So what would it feel like if I were to get in an aircraft and fly hypersonically? You climb into a typical aircraft, it would look different, sleeker, less draggy. You get into an aircraft that is smaller, because it has to accommodate that lower drag. And you would have big engines, and it would look exciting. And I would get into the chair expecting that I’m going to be thrown back into the seat with all this thrust, and I’m going to launch at a great angle of attack, go way up high, and I’ll see flames going by the window, and I’ll lose weight and all these sort of things, but in reality none of that happens. If you’re flying long in a hypersonic aircraft, by and large you really don’t get the sense of the speed. You’re at a higher altitude and the ground is far away, so it’s not rushing past you. You take off and land at pretty much a conventional speed. And you don’t pull great Gs as you go into turns or as you climb out. This is not hypothetical, it’s what we experienced. Or at least, the pilots experienced with things like the SR-71. While it has some monstrous and wonderful engines that do put out some neat-colored flames out of the back, really it’s fairly docile. Once you get up to speed, you can’t really feel that you’re going, in that case, Mach 3+. And then as you come back down, air traffic control really wouldn’t like it if we’re coming in towards the airport at some hypersonic speed, so they’ve got rules. When we fly, if we get below a certain altitude, we have to maintain a speed limit, if you will. So even though we may be in an aircraft that can go hypersonic, as we come in to land, we have to follow the rules and we’re going as slow as everybody else is as we line up into LAX or Philadelphia or what have you. So really, not a big difference, just a big throttle.

Narration: Hypersonic speeds have been achieved. But today’s hypersonic development isn’t just about going fast.

AC: Typically what happens over time, is it becomes an “and” kind of situation. So I want this aircraft to go fast and I want it to be low observable. I want this aircraft to go fast and I also want it to create a small sonic boom. Well, that’s something that shouldn’t go together. Right? Because when aircraft go fast, they do create sonic booms. That’s part of what we were talking about before, that a sonic boom is a very strong shockwave, which is the way that Mother Nature makes everything kind of make sense from a physics standpoint. So you have to have the sonic boom, asking it, an aircraft, to go fast and not make a sonic boom, that’s a new engineering problem. A very different engineering problem than just “make the aircraft go fast”. A very different engineering problem than “make the aircraft go fast and be stealthy”. I think that for an engineer, as they come into an aviation industry, that’s probably the thing that’s most interesting. And it certainly isn’t the engineer of today doing what the engineer in 1960 did of just making an aircraft go fast. It’s “making an aircraft go fast” and all these other things.

EK: So the question that often gets asked is, “Won’t that be really loud inside of the aircraft? Won’t that booming kind of keep me awake?” For the pilot and for the passengers, you don’t hear anything. The boom is simply projected out and down and up, and folks on the ground, they’d hear it. And that’s probably one of the limitations that we’ve had in the past, and why we don’t have supersonic transports, is that boom. The concern of what effects it has on the population below or on the wildlife, whether that’s over land or over sea. And that’s where we’re working other exciting technologies that allow us to create something that flies very fast, but doesn’t create that sonic boom on the ground. All these technologies have endless potential, what you could apply them to. But we’re trying to get rid of the things that are the hurdles or the gates that preclude us from going down those paths. If you talk to the folks that worked the supersonic quiet, business jet type technologies, if you could eliminate that sonic shock, that boom, then it becomes more acceptable to fly over land. Then the reality of getting between Los Angeles and New York in an hour or two becomes a reality. So it’s just getting rid of the negativities so that we can open up the opportunities.

Narration: Hypersonic commercial transport could change the way the majority of the world perceives distance. Just as the first railways brought neighboring towns closer together, hypersonic travel could shorten the distance between countries.

EK: So I don’t know that we’ll ever pursue it at this point in time, but things change. Let’s say we decided that we wanted to make a hypersonic transport. Maybe it’s an outgrowth of the exciting quiet, supersonic jet technology that we’ve got going on now. Ultimately, we need to put passengers into an aircraft, into a kind of hostile environment. We’re going to be going fast, we’re going to be going high, we’re going to be heating things up. But the folks inside want to be able to sit there and enjoy their sandwich, and feel like nothing is going on, everything is happy. There are technologies that we need to be able to maintain, the cabin pressure, in that type of environment, where there’s a large differential between what we need inside and what’s going on outside. Can we make the ride smooth? If we’re flying at a higher altitude, can we ensure that we’re protecting the people from, your know, solar radiation, not as much ozone protecting them. Can we create an aircraft that doesn’t have a lot of drag at those velocities but still allow the people to stand up as they walk to their seat? So there are a lot of things that we have to compromise on when we reach the limits of capability. But there are some things that we can’t compromise on. Safety is a big one. And if it was a commercial application, you still have to have the customer, in this case the passengers, having a desire to be in that condition. If I’m going to pay that much to go fast, I’m going to expect that it’s going to be comfortable.

Narration: In combat, aircraft speed impacts survivability. Hypersonics would be a game-changer for fighter pilots.

EK: For the military pilot, some of the things that you’ll hear them say are “Speed is life.” And as a pilot myself, one of the things that you learn very quickly is altitude and speed are important. You don’t want to give up either one of those.

AC: One analogy you could use to tie evolution of speed, in air travel or air combat, to biology is speed is kind of one of the ultimate advantages when you’re talking about a predator. So if you have an amazing animal, like a cheetah, the whole persona of the cheetah is defined by this burst speed that this animal has, it’s just amazing. And it is what makes it a very effective predator and lets it catch already very, very fast animals, like gazelles, and bring them down. In the same way, air combat is a little bit of a predator kind of existence. Right? If you’re in an air combat situation, you’re either a predator or you’re the prey. And so, I think that the perspective has always been, speed, just like it is important for a cheetah to make sure it’s the predator not the prey, is also important for a fighter pilot to make sure he ends up the predator not the prey. I mean, it also helps to have sharp teeth like the cheetah has, it also helps to have great weapons and sensors, but speed is one of those difference-makers, if you will, that can give you an inherent advantage in a predatory environment.

EK: It’s likened to maybe, have you ever played air hockey? Here you have a puck that sits on a bed of air, and you try and shoot into each other’s goal. And you quickly learn, as you approach the table against your competitor, that the harder and faster you get that puck going, the less they are apt to be able to block it. Because they can follow it as it goes along. So speed becomes important, but there is another attribute that becomes equally important. So imagine you’re playing that air hockey, and your opponent has become pretty good at watching where the puck’s going, no matter how fast you shoot it, and they can block it. So now imagine if, as that puck is going along in a straight line, you’re able to have it turn. Now it becomes virtually impossible to block. And like all the other attributes that we add to hypersonics, speed and maneuverability are key elements of what keeps them in a high-survival mode.

JD: Yeah, when you’re going that fast and you change the direction, the impacts that it can have on the control, the aerodynamics of the vehicle are very significant. We tested, we built platforms, we learned, and those have all been incorporated into our hypersonic platform work today.

AC: So we believe that’s an attribute that we have to cultivate, and you have to work at having. You are not just naturally fast. And it doesn’t feel comfortable to move fast, and so you have to train yourself to do that, and you have to practice it.

EK: The space shuttle, the X-15…these are things that have been going hypersonic for a long time. Will it happen for civil transport? Well, who knows. That’s certainly possible. Is the world big enough for the speed that hypersonics provides? Maybe. We’ll have to see. But hypersonics not only has happened, but it will happen. The exciting part is, all the folks that are graduating now are going to be the ones that define it and create it. It’s like UAVs were 10, 15, 20 years ago. We’re at the cusp of that hypersonic attribute that people will get to be a part of now.

Narration: Inside Skunk Works is produced in Palmdale, California and Fort Worth, Texas. Stay tuned for words of wisdom from Eric Knutson. To read the full transcript of this episode, go to LockheedMartin.com/InsideSkunkWorks.

EK: So as I look back at some of our most successful engineers, and not all of them were engineers, some of them came from very different walks of life…it was important that they studied hard and learned all their core curriculum for their degrees, but equally important was to get a great diversity of experience. Make sure you understand beyond just the discipline that is your chosen goal. If you’re a propulsion guy, you’re certainly going to want to pick up on aerodynamics, maybe some thermo. And whether you’re staying to the traditional engineering disciplines, you may also want to learn a little bit about mission planning or operations analysis. And if you’re going to be trying to create a new system, it would be really good to understand how to build it, understand manufacturing and tooling and fabrication. If you’ve had the opportunity, to rebuild the engine of your car or motorcycle or what have you, if you’ve had the opportunity, to build a computer at home. Get those experiences. Because it’s that diversity that’s going to make you, or differentiate you from everybody else, and make you a Skunk.

Episode 7: Sea Shadow

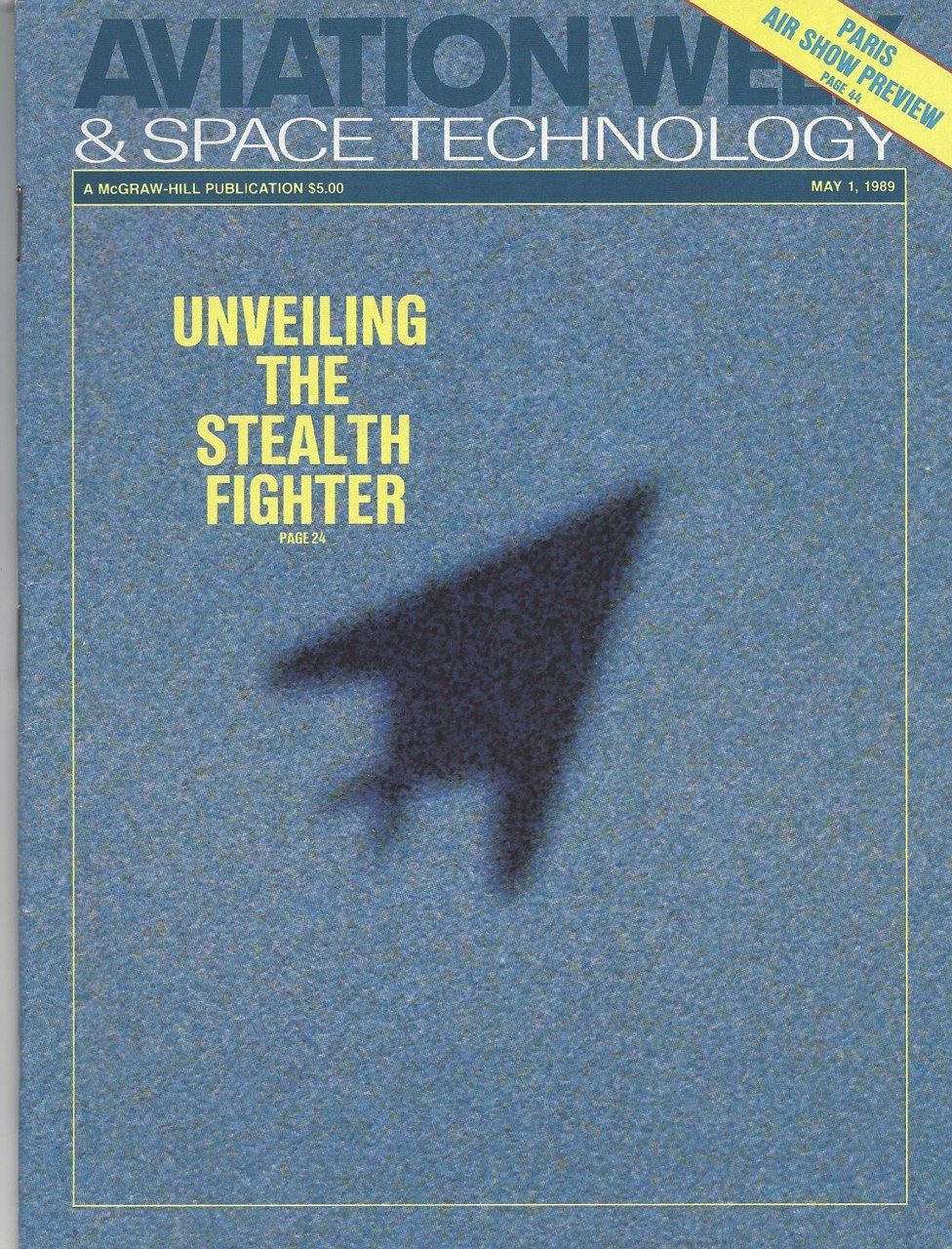

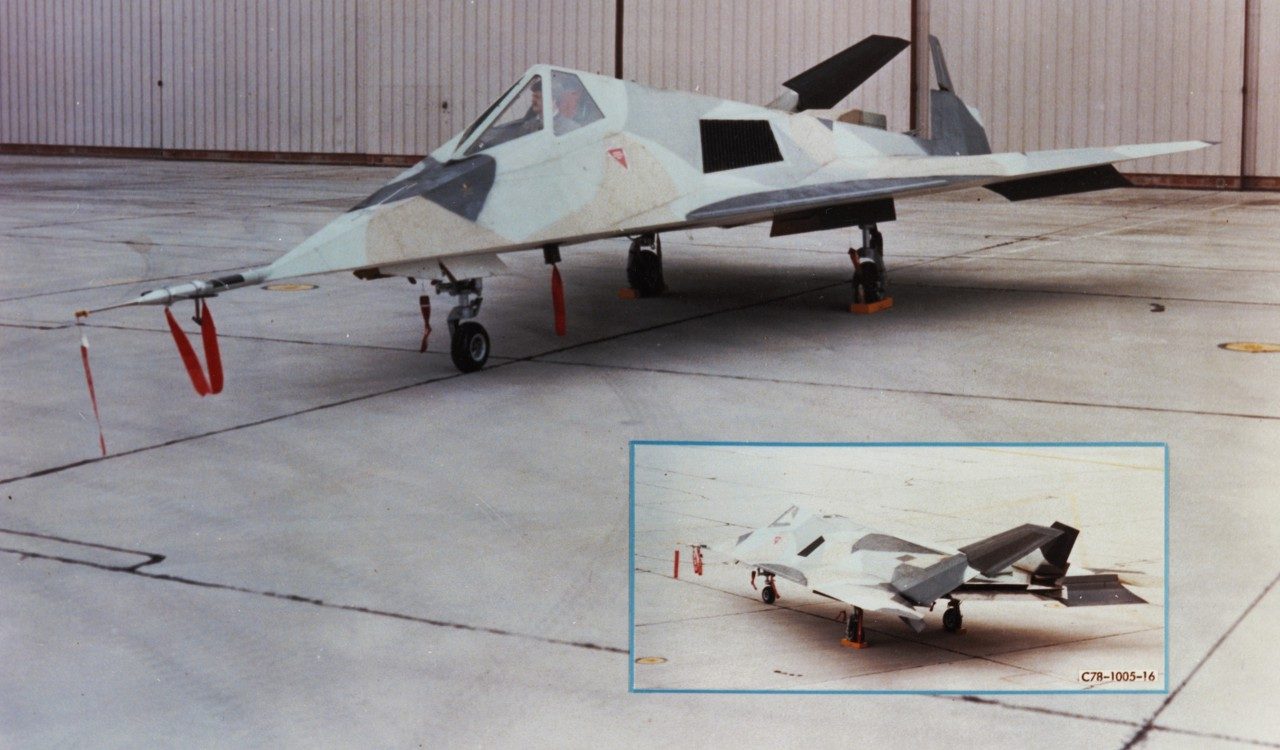

Larry Dilger: In the ‘70s, mid-‘70s, with the experience from the U-2 and the SR-71 under our belt, the value of stealth technology being realized, we brought new people into the Skunk Works® that were knowledgeable of the electromagnetic spectrum, how radars worked. One such young engineer, out of Oregon State, named Denys Overholser, was hired by the Skunk Works®. He found himself working on mathematical codes, predicting all kinds of things, one of which was the radar signature of certain shapes and objects, in the quest to take stealth technology to the next level. U-2 is generation one; the SR, A-12 was generation two; this would be generation three. In those days, everybody in the industry was interested in stealth. We lost most of our airplanes in the Yom Kippur War because they were detected by Soviet radars; they were engaged by surface-to-air missiles that were guided by radars, and we literally could not survive.

Narration: If you’ve listened to our season one episode called Arrowhead, this story might sound familiar. And that’s because we’re going to tell a stealth story that ran almost parallel to the F-117. While the F-117 was in production, there was another stealth vessel in development. And it would require the help of the very same engineers who created invisible jets. Denys Overholser was a young engineer when he came across Russian papers that explained the possibilities of faceted shaping. This moment would propel Denys into developing one of the most important jet technologies. At the Skunk Works®, Ben Rich is coined as the father of stealth, but Denys is like the Wozniak of stealth. It was Denys’ research and development that made stealth-shaping a reality.

Denys Overholser: I had the fortunate situation of being trained inside the Skunk Works®, where these guys were all so smart.

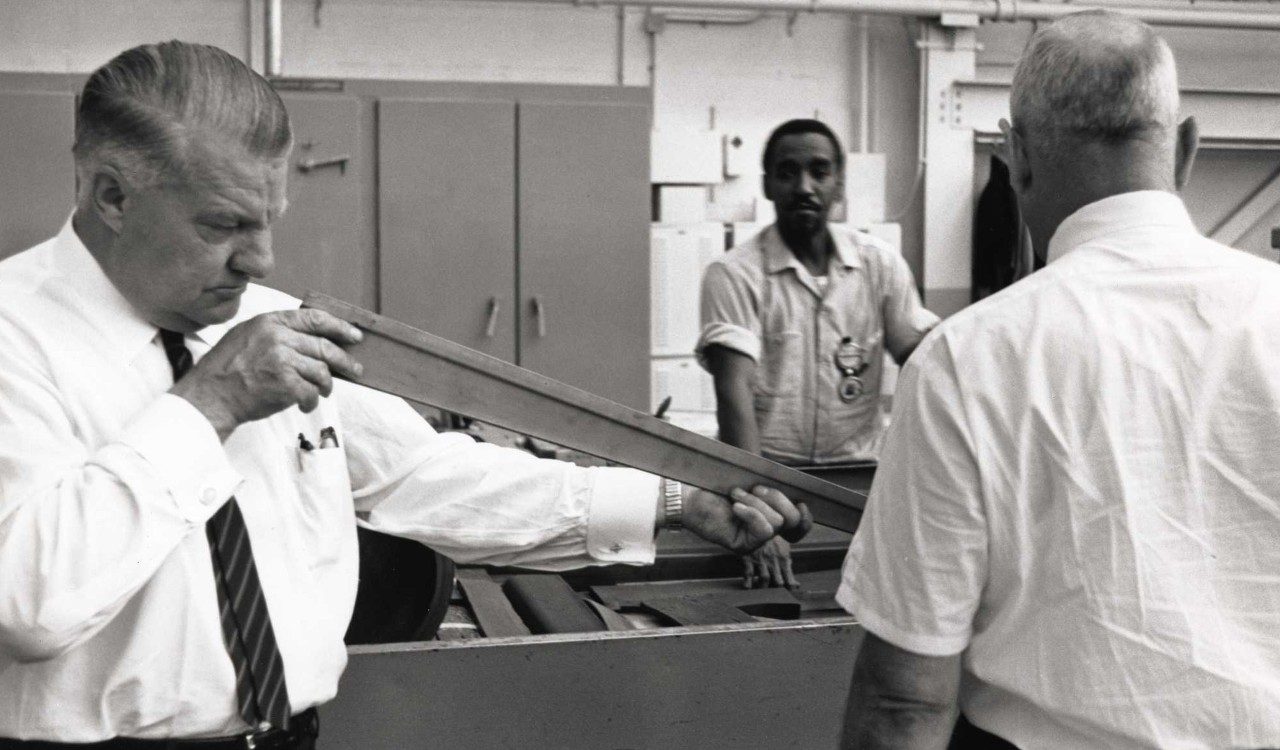

Narration: Early on in Denys’ career, he worked directly with Kelly Johnson to improve the radar cross-section of the DS-21, the Mach 3.5 reconnaissance drone.

DO: And Kelly was directly involved, like I said. He was really the number two radar cross-section expert in the Skunk Works®. We were struggling to get improvements, but he was trying to improve a design without looking at the shape first.

LD: Denys was absolutely intrigued with the idea of faceting, for a couple of reasons. One, if you could break an object into flat plates, you could pretty well calculate how that flat plate looked to a radar. If you assemble the flat plates correctly, you could be virtually invisible to radar, because the energy scatters away from the target, rather than back to the radar.

Narration: This is Larry Dilger, retired Skunk Works® Program Manager. To better picture how stealth-shaping works, Larry has a great analogy.

LD: If you look in a mirror, you see your reflection, right? So any energy that goes, photons that go into the mirror are going to be reflected right back to you. So you’re the radar transmitter, you’re also the radar receiver. You see the image. Take a prism, like might be dangling from a chandelier. Shine a light on it; all of the facets on the prism scatter the light like beams in all kinds of directions. Not all of that light comes back at the observer, ok? All right, so if you would paint that prism with a radar, most of the energy would be scattered in a direction other than the radar, minimizing the radar return. If that return is low enough, it would be lost in the noise. Denys, not being an aerodynamicist, and some of his cohorts, were absolutely convinced that you could apply that to an aerodynamic shape. Aerodynamicists within the Skunk Works® didn’t think so, so the challenge was laid. Denys and some very sharp, but somewhat unsung heroes developed a code called Echo. Echo was used to mathematically evaluate the return, or the radar return, from different objects. Denys was working on things that were very, very unconventional, and literally scared most aerodynamicists. How do you make a box fly? But by using Echo, Denys put together a very convincing case to Ben, that if you really wanted to survive it would be best not to be detected. And if you don’t want to be detected, you don’t want to return your image to the radar. Denys convinced Ben, who convinced DARPA and some other sponsors, including the Air Force, to look at this faceting thing a little more closely.

Narration: Skunk Works® began developing Have Blue, or as Kelly called it, the “Hopeless Diamond”. This was the predecessor to the F-117. Denys used his program, Echo, to test faceted configurations until they had a configuration that was invisible.

DO: Since we had the computer Echo, and we could compute the changes overnight, and the competition had no computer code. Who was going to get to the right answer first, you see? Well, like I say, it wasn’t a competition.

LD: We were able to predict the signature, match the signature to the test data, and the results were compared to the predictions. And soon the nonbelievers started believing.

DO: There was a “cup of coffee” bet. Kelly would go that far. But he bet Ben Rich a cup of coffee that the DS-21 would be better than “those Hopeless Diamonds that Denys was coming up with”. Well, Kelly lost the bet, and it was the only bet that Ben Rich ever won from Kelly. When that happened, everybody said “This is real!” The rumors spread through the Skunk Works® like you wouldn’t believe.

LD: The “Hopeless Diamond” was proof that you could not only minimize the signature return, the echo from a target, but you could actually calculate exactly what that signature would look like. If you could do it to an airplane, what can you do to a ship or to other objects? Denys had won Ben’s attention, trust with the “Hopeless Diamond”, with Have Blue; F-117 was in the process of being created. So Ben was the guy that really felt that something was needed for surface vessels. Denys, who worked a hundred and, well more than 24 hours a day, more than 168 hours in a week it seems, (the guy is absolutely a machine!) sat down with a pencil and pad and started sketching out what he thought a ship should look like. A faceted ship, much akin to the Have Blue and it’s predecessor, the F-117, but suitable for a marine environment; parts of the environment don’t come into play in an aircraft like they do on the surface of the ocean. The Navy was interested, DARPA was interested. DARPA is in the business of inventing game-changing technology, so it was a natural fit for DARPA. The government and people within the corporation were a little dubious about the Skunk Works®, the inventors of the SR-71, designing boats; but within the corporation, we had some very, very sharp marine engineers. Advanced marine systems up at Sunnyvale were part of the corporation. Those are the guys that know how the ship is going to behave, you know, in a marine environment. What will make the ship survivable from a structural point of view, how to scale things, propulsion systems, the draft, the depth that the ship is sitting on, all of these things. It was decided that they should be brought in and they should guide the development of a viable concept. They knew that most ships had certain issues that had to be dealt with, one of which had to do with sea-keeping. If you look at the surface of the ocean, the surface isn’t flat. You get waves, you get currents that cause a ship to rock back and forth. You want the ship to slice its way through the water, not plough its way through the water, as a conventional V-hull would do. That disturbs the water. As the surface of the water is disturbed by something moving through it, it too has a signature, it’s got a background. On a real rough sea, if you’re looking for something down in the water, the fact that the water has been scarred could help. You might be able to follow some of that scarring to its source. An airplane flying through the air sometimes leaves a contrail. If a guy on the ground is looking for an enemy airplane and he sees the contrail, he can’t see the airplane but he can see the contrail. You don’t want to disturb the environment that you’re in, you don’t want to be a mirror, and you don’t want to help the bad guy hurt you. So it’s kind of the same philosophy; little different environment, little different set of sensors, which of course requires different levels of expertise. Denys and guys came up with a shape that they thought was ideal. The catamaran offered an ideal platform because it sat in the water on very narrow struts, supported by pontoons below the ocean surface. A SWATH ship stands for Small Water Airplane Twin Hull. SWATH is a very specific type of catamaran. There are lot of SWATH ships out there; the US Navy today uses SWATH ships, that aren’t stealthy in any way, shape or form, for a variety of missions. Most conventional ships, V-hull ships, have a fairly significant draft. In other words, there’s a good chunk of that ship under water. If it’s a large ship, you have a Dickens of a time getting very close to land. You can almost put a catamaran on the beach. It sits higher in the water, it can slice nicely through the water, minimizing most of the drag. You add canards, fins, and now as you go through the water, you can trim that ship. It’s like the control surfaces on the airplane; you want to trim those such that the aerodynamic resistance, or drag on the airplane, is absolutely minimized. So all of these things came together to create what became the Sea Shadow.

Narration: Sea Shadow, an X-ship built for the United States Navy. The mission was to get as close to invisible as possible. Testing stealth technology for naval vessels, the program was a collaborative effort between DARPA, the US Navy, and Lockheed. Larry Dilger was one of several Sea Shadow Skunk Works® program managers throughout the lifespan of the program.

LD: The real promise to DARPA and its interested partners, the US Navy, was to come up with something that not only validated the concept of reduced signatures from ships, but also would provide a platform for evaluating a variety of materials. Different materials on the surface of the object; different mechanisms: antennas, windows, appendages; all of these things. If you come up with something that has a minimal signature, then you can add these things and see what their individual impacts are. Shape alone doesn’t make something necessarily as small a signature as is necessary. Sometimes there’s material technologies involved. We had within the Skunk Works® a materials group; those guys knew how these materials behaved, you know, sitting on a hot ramp in the middle of the summer in the desert somewhere; or at fifty-, sixty-, seventy-thousand feet that’s very, very cold when you go slow, but gets very, very hot when you go fast due to aerodynamic heating. But how would they behave on a surface ship? Would you have to reinvent all that technology or some of that technology? Was it applicable to different platforms? And we were responsible for providing a lot of those materials; those were all homegrown.

Narration: Part of Skunk Works®’ role on X-programs is to foresee future technologies and try to stay ahead of the curve.

LD: When all of this, starting with the third generation of stealth technology, started bubbling up, the government had a guy, named DeLauer, who came out with guidelines, classification guidelines for low-observable technology. Those guidelines were suitable at the time but did not take into account what was actually possible. It took into account what was proven, what common sense said. But when the real floor was discovered, how good things really could be, documents like that, that guided the industry and the government, all of that had to be rewritten. And at that time, the curtain, rather than being raised, was lowered. Because again, every measure has a counter-measure.

Narration: Sea Shadow would require testing facilities, and test facilities for an X-ship did not exist.