Skunk Works® Stands Up New Virtual Engineering Environment

Within the secretive confines of Lockheed Martin Skunk Works an engineering group, named Virtual Prototyping, is leading the way in Digital Transformation.

A Transformative History

For nearly four decades our Virtual Prototyping team has been perfecting and innovating Digital Transformation methods to pave the way in this crucial space.

The team has led Skunk Works through its Digital Transformation journey from the beginning, including the transition from analog drawings to 2D CAD, to 3D solid modeling, to parametric modeling, digital mockups and digital twins, to augmented/virtual/mixed reality, hardware and software innovation and much more.

We’ve continued to invest in multiple advanced visualization facilities and capabilities that have helped deliver technologies to our customers ahead of need.

The VEE: The Place to Be

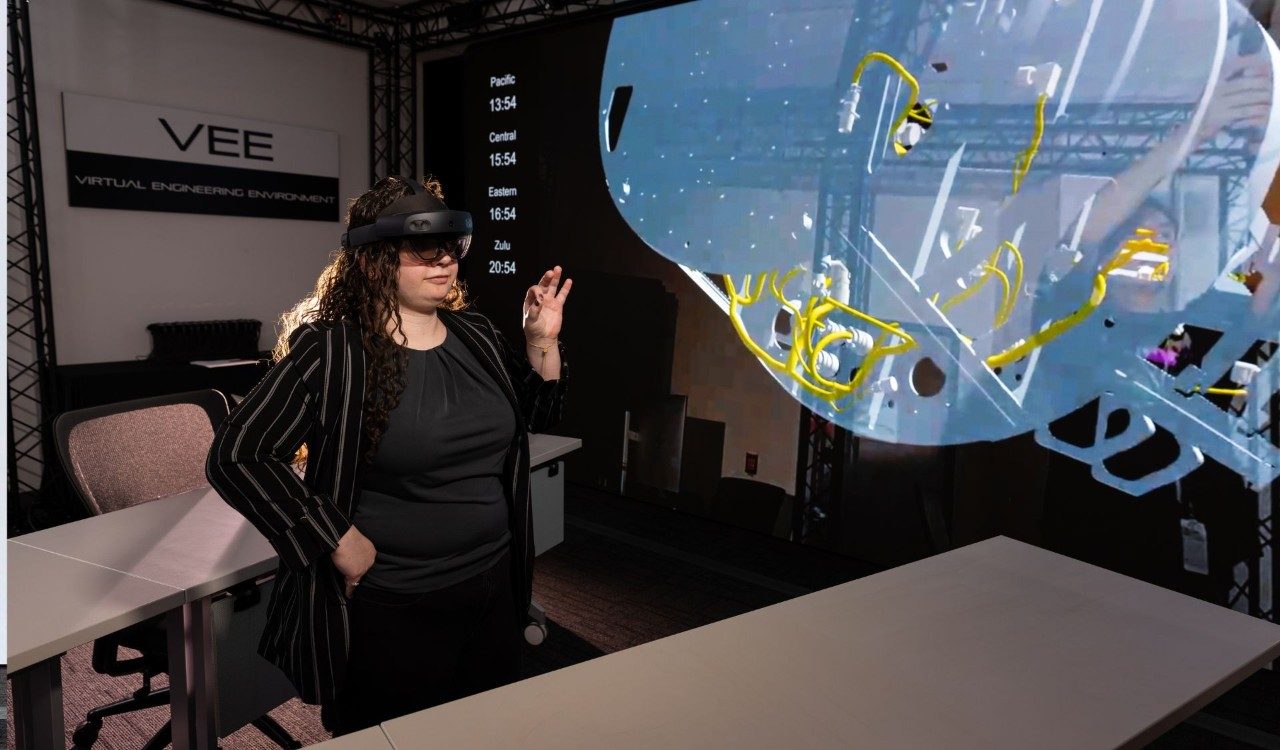

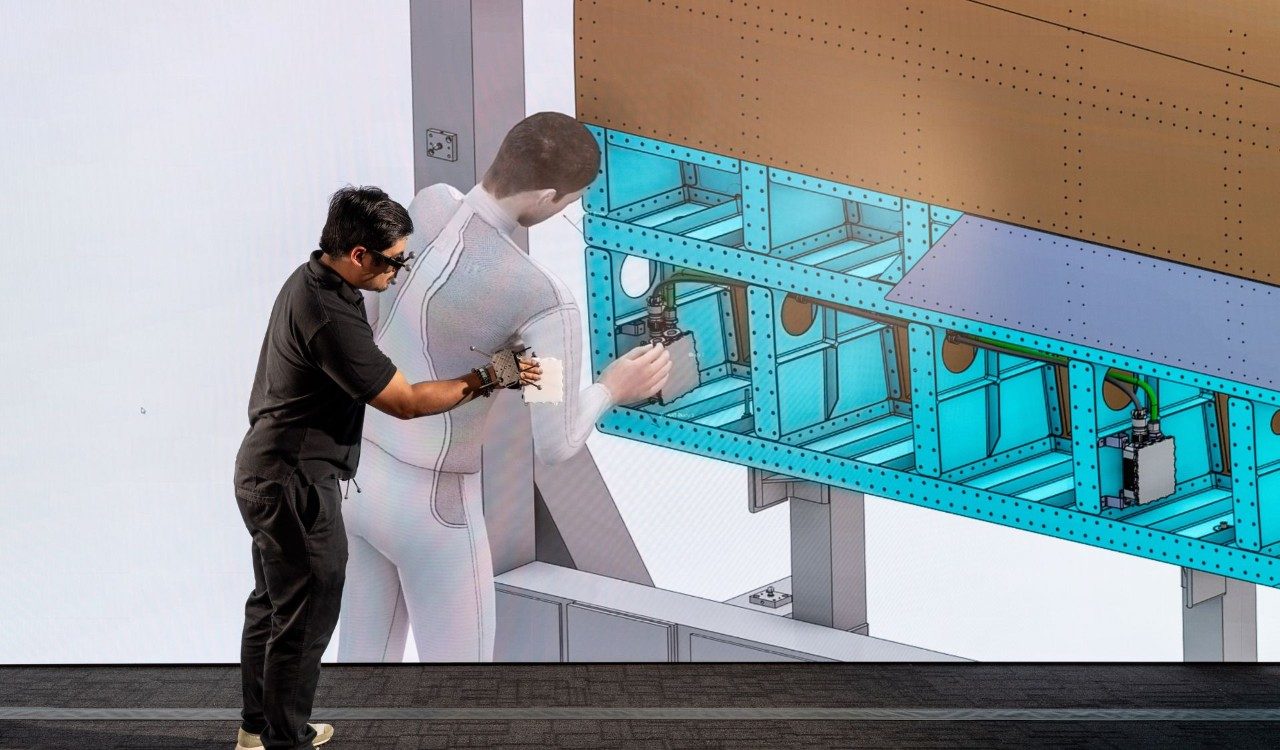

Recently, this team stood up an advanced visualization engineering facility that will speed engineering development, increase collaboration, improve decision making, and drive affordability.

This facility, located in Palmdale, California and named the Virtual Engineering Environment (VEE), is a shared workspace that allows engineers to virtually design, manufacture, test, and analyze various systems, products, or processes using computer-aided tools and software. This virtual environment replicates real-world conditions and enables collaboration among teams working on a project, regardless of their geographical location.

O'Brien continues, "These digital and virtual technologies – all part of our 1LMX transformation – empower and equip our teams to make informed decisions that decrease cost, support delivery schedules and mitigate risk while improving quality,"

The VEE is highlighted by its large format PowerWall display system. The LED PowerWall is a low profile, ultra-high-resolution, stereoscopic-capable display spanning from floor to ceiling to enable full-scale, 1:1 viewing of virtual content.

The VEE’s capabilities represent 1LMX by providing an experiential method for understanding and innovating through an integrated digital thread, model-based approaches, and various digitally enabled techniques including but not limited to:

- Virtual, augmented, and mixed reality

- Modeling and Simulation

- Design for “X” engineering

- Interactive digital twins

- Virtual collaboration

- Real-time photo-realistic rendering

- Motion capture

The VEE can be rapidly reconfigured for application across many engineering disciplines and use-cases.

“By using the capability in a variety of ways, Skunk Works is able capitalize on its investment and influence best practices across multiple engineering disciplines and programs to enable widespread efficiency and problem solving,” said O’Brien.

The VEE enables enhanced understanding and innovating where our teams are empowered and equipped to make informed decisions that decrease costs, support delivery schedules, and mitigate risk while improving quality. The VEE is transforming our approaches to deliver the speed, agility and insights our customers need to stay ahead of the technological curve.