Additive Manufacturing Expansion Helps Meet Demand for Advanced Capabilities

For years, people have used desktop-size 3-D printers to create toys, art and even kitchen gadgets. At Lockheed Martin, we’re taking 3-D printing, or additive manufacturing (AM), to new heights, creating parts for our advanced capabilities using large format machines the size of a semi-truck. We remain committed to leveraging cutting-edge technology that ensures we stay agile, dependable and responsive to the evolving needs of our customers.

We recently added 16,000-square-feet of state-of-the-art AM space to our Grand Prairie, Texas, facility. This expansion includes some of the largest format, multi-laser machines in Texas, as well as heat treatment and inspection equipment that enables rapid development and production of AM parts across the corporation.

“We continue to invest in AM technology to provide value for our customers in a way that empowers our engineers to innovate and rapidly integrate new product designs and capabilities to the production floor,” said Tom Carrubba, vice president of production operations at Lockheed Martin Missiles and Fire Control. “This allows us to create affordable and modular designs that can simplify both high and low-volume production processes.”

Transforming Product Design and Development

The expansion leverages one of our existing machining hubs and supports our customers’ immediate and future product needs across Lockheed Martin and drives continued AM growth in the industry.

“As part of our 1LMX digital transformation initiative, we are implementing AM in the early phases of our new product designs as a technical risk reduction tool,” said Hector Sandoval, a Lockheed Martin fellow. “Other benefits of AM include improved product performance, as well as reduced development and lead time of our product portfolio.”

Our 16,000-square-foot expansion includes large-format, laser powder bed fusion machines.

The machines used in our facilities can produce intricate geometries and lightweight structures which reduce machining operations, lead time and material waste by manufacturing near finished parts. Additionally, AM allows for the creation of concepts that were previously unattainable and increasing capacity and agility with our supply chain partners supporting a more robust industrial base.

“Using this state-of-the-art, large platform AM technology at Lockheed Martin enables us to rapidly iterate and manufacture all of our products, resulting in savings and design freedom for all of our customers,” said Brian Kaplun, a Lockheed Martin fellow. “AM lives in the digital world and this allows us to support our customers in a far more nimble and responsive fashion than if we were using traditional design and manufacturing methods.”

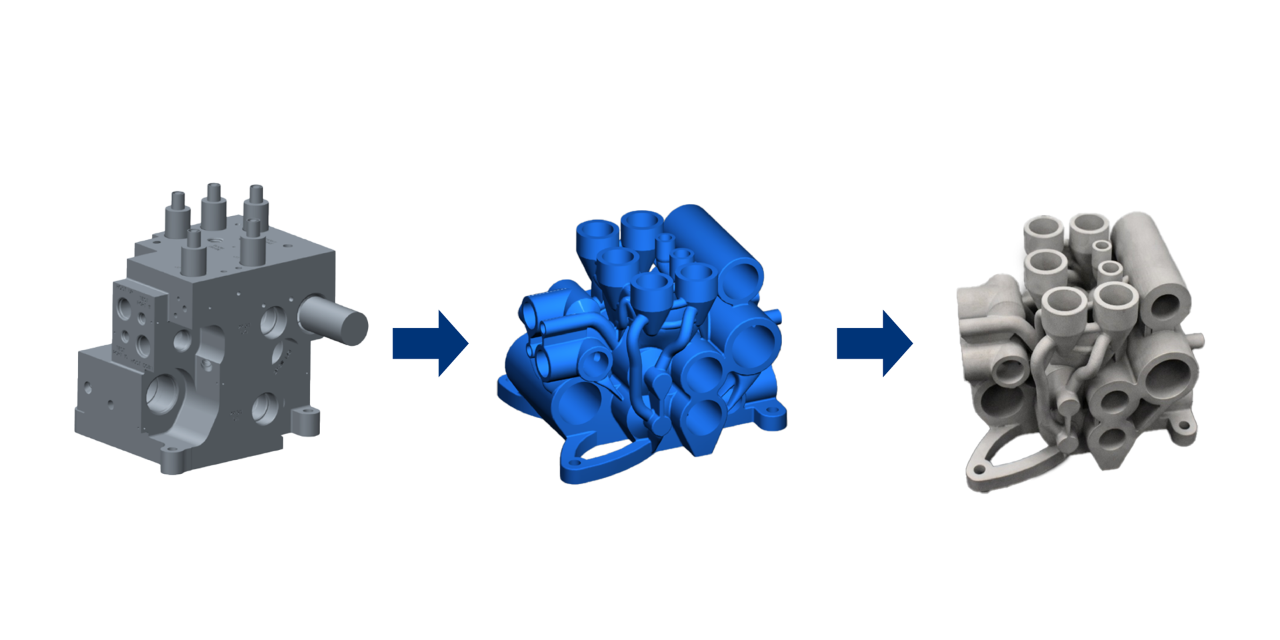

A hydraulic manifold 3-D-printed part. The team leveraged the design freedom afforded by AM to redesign a part that was traditionally machined from a large block of aluminum. Creating more direct and better flowing pathways between hydraulic connections increases performance while achieving significant weight savings.

Decades in The Making

AM processes are something we’ve honed for decades at Lockheed Martin. Through this technology, we’re able to deliver our systems with speed, agility, innovation and competitiveness. A key tenet of our digital and business transformation processes, AM supports our 21st Century Security® solutions with benefits realized across the entire lifecycle of our products, keeping our customers Ahead of Ready.

The digital nature of AM enables manufacturers to precisely control the production process, ensuring high levels of accuracy and consistency and resulting in significant benefits in repeatability and qualified processes for our customers. Additionally, AM designs can be iterated, optimized and produced more efficiently than traditional manufacturing methods, reducing time and cost while ensuring high-quality parts.

AM in Practice

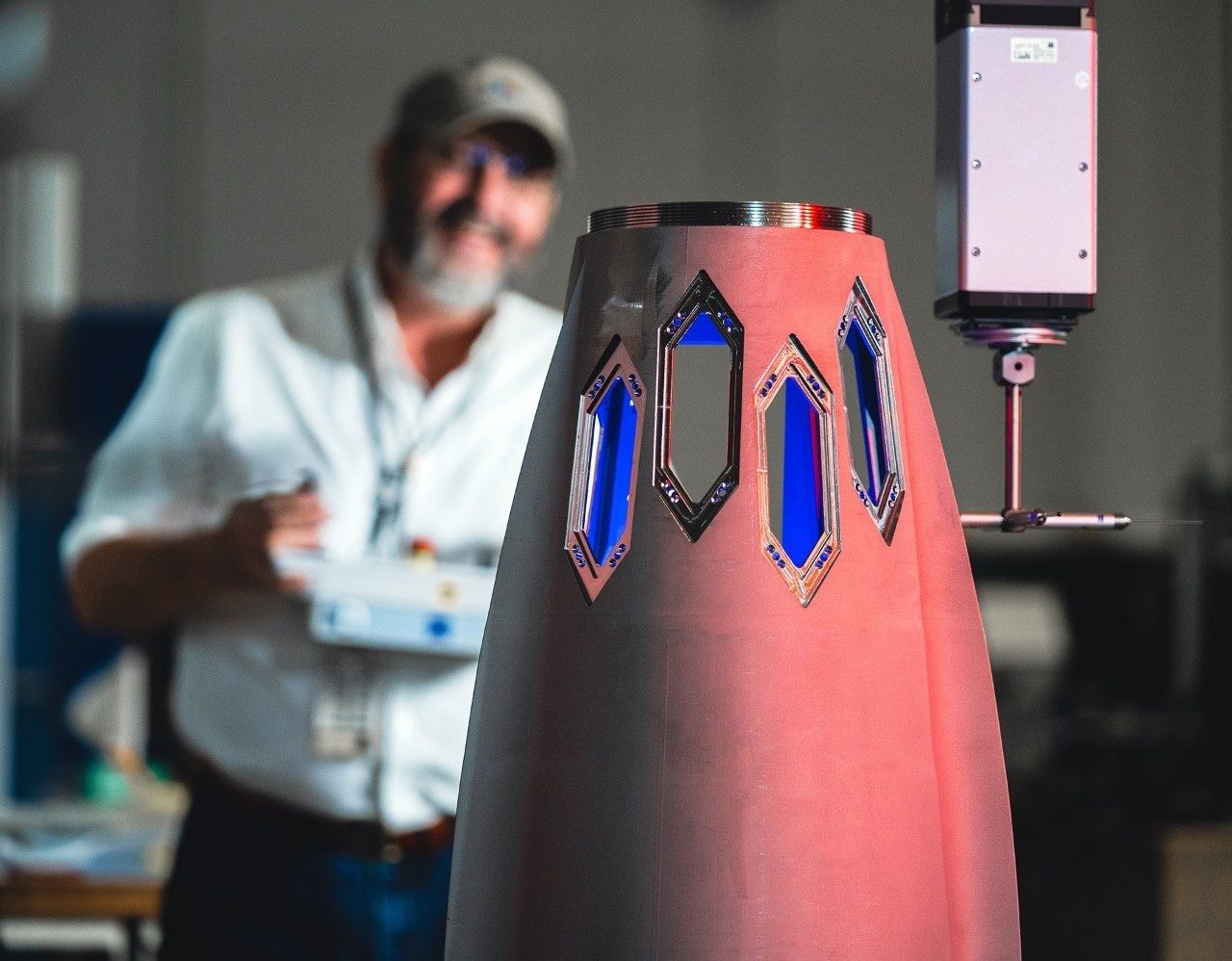

For example, in developing the multi-mission Mako™ hypersonic missile, engineers used AM to make guidance housing and tail fin parts. They demonstrated that these critical assemblies met requirements at a fraction of the cost - a staggering 1/10th - and reduced production time, making it 10 times faster and cheaper compared to conventional subtractive methods. In a customer space where agility, speed and affordability are king, AM is helping to move the needle.

Products like Mako have implemented AM technology.

We’ve also implemented AM technology on many new and legacy programs such as printing F-35 simulator cockpits and components on GMLRS.

By using a model-based engineering approach and leveraging AM expertise, we redesigned a GMLRS antenna assembly test unit, reducing the number of parts. This enabled cost savings per unit and reduced months off our production schedule driving solutions faster and more affordably.

There are significant AM opportunities in operations on our current production programs. This may include greater cost and schedule savings (from years, to months, to weeks). The ability to produce much larger structures with these AM systems is a competitive advantage against near-peer threats and provides unique solutions for national security.

AM also enables technical and supply chain-risk reduction. By using AM as replacements for items such as brazements, heat exchangers, castings, etc., we can consolidate parts and reduce the product design phase and manufacturing lead time.

Investing in the Future of AM

In 2022, the White House announced AM Forward, a voluntary agreement designed to increase resiliency and innovation in U.S.-based supply chains and manufacturing. Lockheed Martin committed to conducting research to improve AM performance, drive critical AM development standards, and further participate with academia in workforce development and college programs.

Following the launch of AM Forward, Lockheed Martin announced a strategic investment with Sintavia to explore AM technology opportunities, leverage in-house capabilities and external investments. This collaboration demonstrates our commitment to expanding the use of AM and creating a resilient supply chain base.

What’s Next

Lockheed Martin is committed to continuing to lead the industry and drive new opportunities to reimagine AM by supporting production and development of the U.S. supply chain and workforce. These investments embed AM as a core element in our current and future designs.

As we continue to qualify more products for critical flight hardware and production, the potential for AM to transform the way we design and manufacture our products is endless.