Our UK Supplier Policies & Guidance

Goods and services provided by our suppliers have a key impact on the quality of the products, solutions and services we offer our customers. To maintain a high level of quality, we are determined to establish and maintain close and long-lasting relationships with our suppliers. Any questions can be sent to supply.lmuk@lmco.com

Current versions of the Quality Requirements & Guidance for Suppliers and Potential Suppliers to our Ampthill Site, Bedfordshire:

- QM003 Quality Requirements for Suppliers reflect the quality flow down requirements of LMUK customers. Archived copies of previous version of QM003 are available below.

- SQAG001 First Article Inspection Guide provides directions on how to identify, plan for and satisfy Lockheed Martin UK Ampthill specific requirements for completing a compliant First Article Inspection (FAI). It is based on the latest revision of AS9102 and overall LMUK expectations.

- SPG01 Special Processes Guidebook provides further information on special processes.

- RCCA – Root Cause Corrective Action Problem Solving Guidebook sets out the steps that should be taken using the 8D methodology when problem solving with root cause corrective action.

- F0389 Deliverable Quality Plan Template is an optional form to assist suppliers in presenting a detailed quality plan on how the supplier intends to meet the QM003 requirements.

- F0577 Supplier Deviation Request form is an optional form to assist suppliers requesting a production permit or concession in accordance with QM003.

- 1QA734-D01 LMUK Ampthill Foreign Object Damage Prevention is the LMUK Ampthill policy on FOD prevention. It can be used by our suppliers as a source of information and best practice around preventing FOD in their deliverables to Ampthill.

Lockheed Martin Engineering Materials Database

Lockheed Martin UK – Ampthill have developed Classification Codes for various materials. For more information and guidance see the LMUK Ampthill Materials Database Guide.

LMUK Ampthill Engineering Materials Database identifies material classifications and acceptable alternatives for use only where a material classification group is specified on Lockheed Martin drawing. Refer to guidance document for further information.

LMUK Ampthill Materials Database Archives

- Version 7 - 01/06/2023

- Version 6 - 01/09/2022

- Version 5 - 22/09/2021

- Version 4 - 12/05/2021

- Version 3 - 28/10/2020

- Version 2 - 03/09/2020

- Version 1 - 23/08/2020

Counterfeit and fraudulent items

There is large, profitable and growing capability by unscrupulous organisations to counterfeit or fraudulently produce and sell aerospace & defence grade components and materials as genuine.

The world-wide trade in these illegal items is worth £ multi-millions per annum with a large proportion originating from the Far East.

Manufacturers of aerospace & defence equipment are increasingly at risk of unwittingly embodying these counterfeit or fraudulent items into their deliverable products with potentially catastrophic consequences.

This risk has the potential to manifest at any point in the supply chain so Lockheed Martin demands equal vigilance from their sub-tiers throughout the supply chain in avoiding and detecting all items that are not genuine.

Definitions

Counterfeit Item: An item confirmed to be a copy, imitation or substitute that has been represented, identified, or marked as genuine, and/or altered without legal right with intent to deceive or defraud.

Fraudulent Item: Any item misrepresented to the customer as meeting the customer’s requirements.

10 Warning Signs

Be suspicious of counterfeit and fraudulent items if you encounter any of the following warning signs:

1) |

Identification Markings |

Alterations, wrong size, location, marking method incorrect, smudged or blurred, lot or batch numbers missing, incorrect suppliers logo |

2) |

Product Condition |

Resurfaced / refinished, evidence of re-work, wrong colour, shape or size, evidence or previous use (used item) |

3) |

Paperwork / Certificate of Conformity |

Accompanying paperwork has poor spelling or grammar, errors or evidence of tampering, missing information or does not relate to the delivered product |

4) |

Lot Information |

Unusual serialisation or reference numbers, lot information missing |

5) |

Chain of Ownership |

Unverifiable traceability to source |

6) |

Unusual Location |

Items delivered from a location differing from previous or from prohibited countries |

7) |

Low Price |

A price significantly lower than historical pricing data or market norm |

8) |

Availability |

Obsolete or scarce items suddenly becoming available |

9) |

OEM Certification |

Unavailable OEM certification or uncertified OEM |

10) |

Unfamiliar Supplier |

Supplier or agent / stockist not known or previously used |

Further Assistance

For further assistance or to report suspected counterfeit parts, contact the Quality Manager at the Lockheed Martin UK division you are contracted to supply or Konrad Burgoyne.

FOD Prevention

In the aerospace and defence industry, Foreign Object Damage (FOD) costs billions in the form of schedule delays, rework, injuries, and product losses – a bit of debris lodged in the right place could be enough to drop an aircraft right out of the sky. The full impact of FOD is difficult to measure, as often times FOD will cause other defects/damage as it migrates within an assembly, creating additional costs that may not be captured. Ultimately, the biggest cost of FOD is your company’s reputation – delivering products that are not FOD-free sends the message that you do not have control over your manufacturing processes or that you don’t care about the product’s performance.

A Foreign Object is a substance or article alien to a product or system that may or may not cause Foreign Object Damage if not removed or controlled and allowed to migrate onto the product, system, or introduced into an operational environment

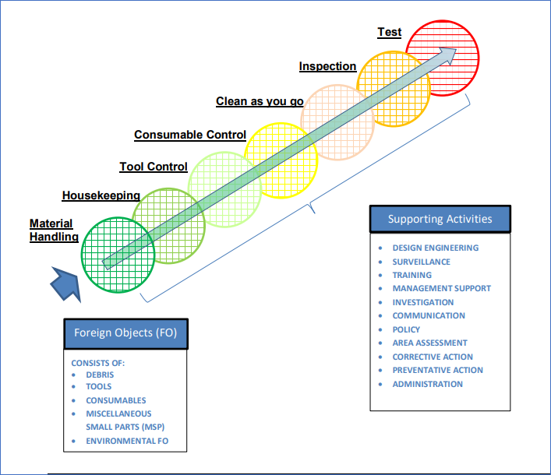

Ampthill’s FOD Policy is a detailed breakout for preventing FOD during fabrication, manufacturing, modification and test. Successful FOD prevention in this environment relies on the proper assessment of FOD risk combined with the appropriate controls to mitigate the risk. As no single process is expected to be 100% effective at eliminating the risk of FOD, LMUK Ampthill employs a layered approach designed to progressively reduce the presence of Foreign Objects to mitigate the risk of FOD as shown:

Further Assistance

For further assistance on preventing FOD, contact the Quality Manager at the Lockheed Martin UK division you are contracted to supply, or Konrad Burgoyne